The tire-type mobile crushing station has emerged as a key innovation in the evolution of crushing and screening technology. With outstanding mobility, flexible modular design, and strong operational adaptability, it is now a vital production tool across multiple industries—such as mining, construction waste management, municipal infrastructure, and aggregate production. It solves the mobility limitations of traditional fixed crushing lines and reflects the industry's shift toward efficiency, intelligence, and sustainability.

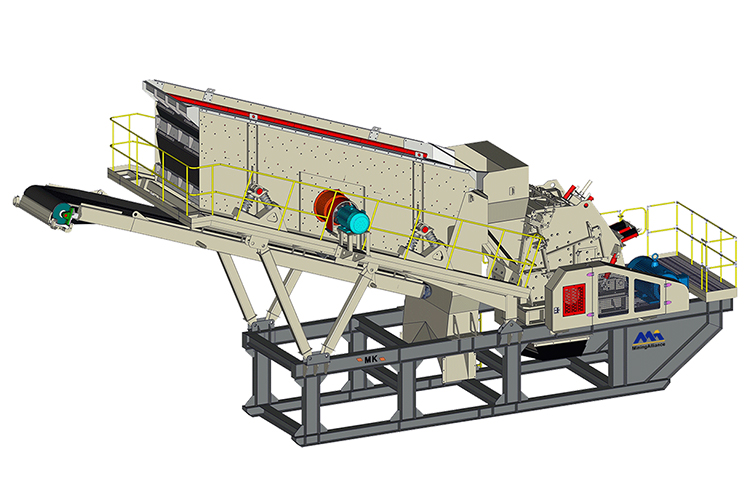

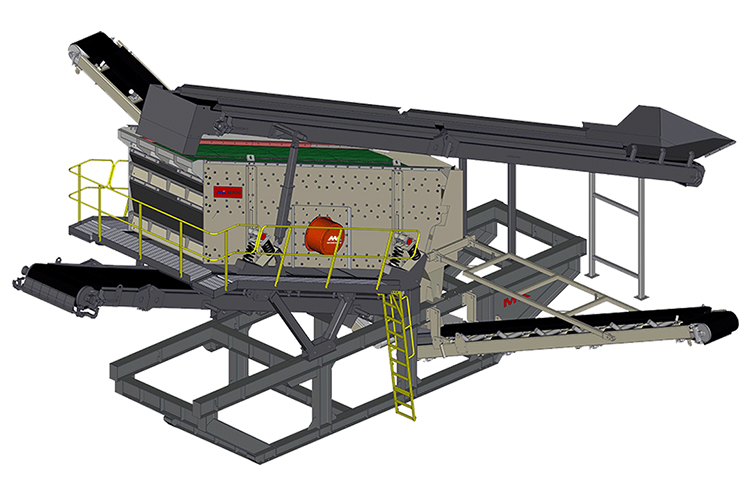

The station typically includes five core modules: feeding system, crushing host, conveyor system, control unit, and wheeled chassis. Depending on material characteristics and job site conditions, it can be equipped with jaw crushers, impact crushers, cone crushers, or vertical shaft impactors to handle various size reduction needs. Its chassis, built with heavy-duty axles, offers off-road capabilities and road adaptability, enabling quick transitions even in rugged environments.

1. Technical Highlights

- Flexible Deployment and Fast Relocation: The tire-mounted structure allows for setup without ground foundation and smooth mobility in urban, mountainous, and mining terrains.

- Integrated Operation: The all-in-one structure, combining crushing, screening, and conveying, enhances productivity and shortens project timelines.

- Smart Control System: Featuring a PLC-based control system for one-touch startup, parameter adjustment, coordinated equipment operation, and fault alerts, it reduces manual intervention.

- Eco-Conscious Design: Equipped with multi-stage dust suppression and silent generators, it meets urban environmental standards and minimizes noise and pollution.

- Simple and Reliable Maintenance: Its modular architecture ensures easy replacement of components, shortened maintenance cycles, and consistent operational uptime.

2. Key Application Scenarios

- Construction Waste Recycling: Deployed directly at demolition sites to crush concrete, bricks, and rebar-laden debris into usable aggregates for bricks and road base materials—cutting transport and landfill costs.

- On-Site Mining Operations: Ideal for surface mining and aggregate quarries, enabling near-face crushing and reducing hauling distances for improved efficiency.

- Road and Bridge Construction: Utilized for in-situ crushing of old road materials, supporting recycling efforts and supply of new aggregates on demand.

- Water Infrastructure Projects: Deployed in reservoirs, dams, and canals to supply screened aggregates with high efficiency, aiding construction schedules.

The rising adoption of tire-type mobile crushing stations signifies a comprehensive upgrade in crushing operations. Through innovation and integration with smart systems, these machines boost operational efficiency, promote circular resource utilization, and align with environmental goals. As "green mining" and "intelligent construction" become standard, tire-mounted crushers are set to play an increasingly central role in the future of sustainable infrastructure.