With the rise of carbon-neutral policies and sustainability initiatives, resource recycling has become a crucial issue in construction and waste management. Tire-type mobile crushing stations, with their high-efficiency crushing, screening, and mobility capabilities, are now widely used for recycling construction waste, reclaimed concrete, industrial by-products, and more—supporting the shift to greener and more efficient production models.

Traditional recycling approaches rely on centralized treatment and heavy transport, leading to inefficiencies and secondary pollution. Tire-type crushers, however, enable on-site crushing and real-time screening, drastically reducing haulage distances and energy consumption while improving the localization, value, and low-carbon utilization of resources. Thanks to their mobile platforms and intelligent systems, these units can adapt to varied job conditions and significantly improve operational efficiency.

1. Equipment Advantages in Recycling

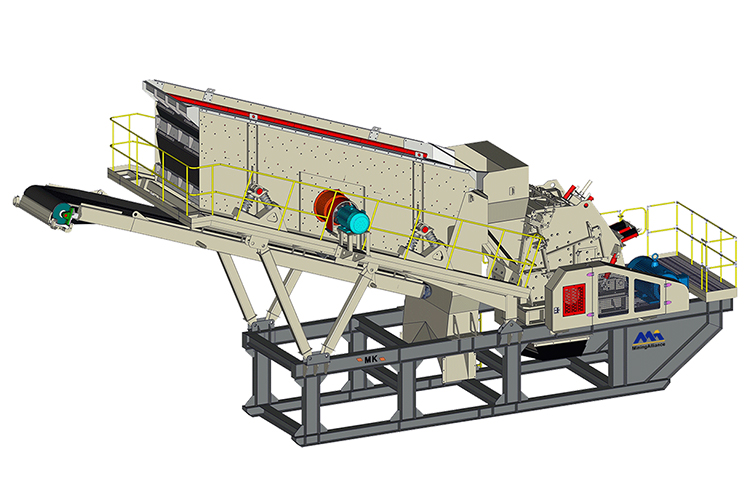

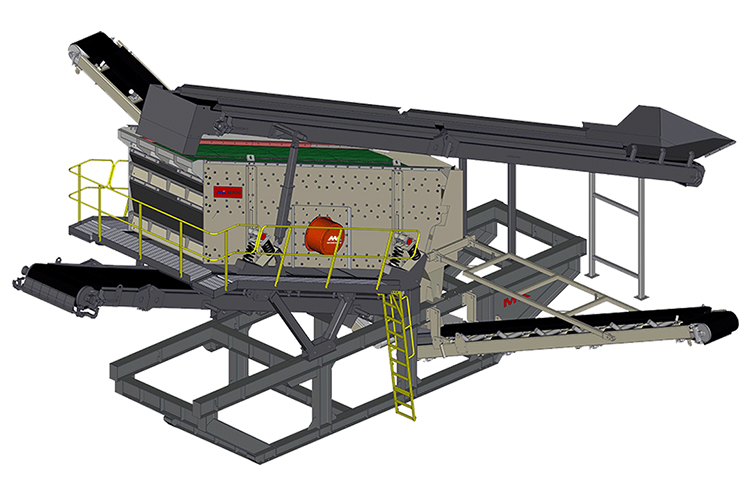

- On-Site Processing Reduces Costs and Emissions: Their wheeled chassis allows deployment directly at demolition, construction, or mining sites, eliminating the need to haul waste material to fixed facilities—cutting transport energy use and labor expenses.

- Modular Design for Varied Materials: Flexible configuration of jaw crushers, impact crushers, cone crushers, and screening modules enables efficient processing of bricks, concrete, rebar, cement residue, and industrial slag.

- Smart Control Systems: Equipped with load monitoring, remote control, fault alerts, and live video monitoring for safer, more efficient operation.

- Eco-Friendly Design: Integrated dust suppression, noise reduction, and enclosed conveyors meet urban environmental standards and minimize dust and noise pollution on site.

- High Material Recovery Rates: Advanced screening modules allow for material sorting and recovery, producing high-quality recycled aggregates for bricks, permeable pavers, concrete, and more.

2. Case Studies in Action

In urban redevelopment projects, tire-type mobile crushers are frequently deployed for construction debris recycling. For example, in one major city renovation, the equipment was placed directly on-site to crush and sort concrete, bricks, and rebar, processing over 2,000 tons daily. The recovered materials were reused for paving, backfill, and foundation work—reducing material procurement costs and promoting circular construction.

In industrial waste treatment, steel mills and power plants have adopted mobile crushers for slag, fly ash, and furnace waste pre-treatment. These materials are converted into road subbase, cement additives, and construction aggregates. Compared to fixed systems, tire-mounted units offer faster relocation between stockpiles and better efficiency under changing operational needs.

Under government policies promoting a "resource-efficient and eco-friendly" society, tire crushers are becoming essential tools for cities to achieve sustainable solid waste management. Their deployment has added momentum to green urban development.

3. Future Outlook

Tire-type mobile crushing stations are evolving toward greater intelligence, environmental compliance, and output capacity. With the integration of IoT and big data technologies, they are poised to play a central role in the resource recycling value chain. As the recycled materials market matures, these machines will be increasingly applied in green construction sites, zero-carbon cities, mine reclamation projects, and eco-industrial parks.

As carriers of green technology, tire-type mobile crushers are reshaping how resources are recovered—paving the way for waste reduction, resource reuse, and environmental protection in modern infrastructure.