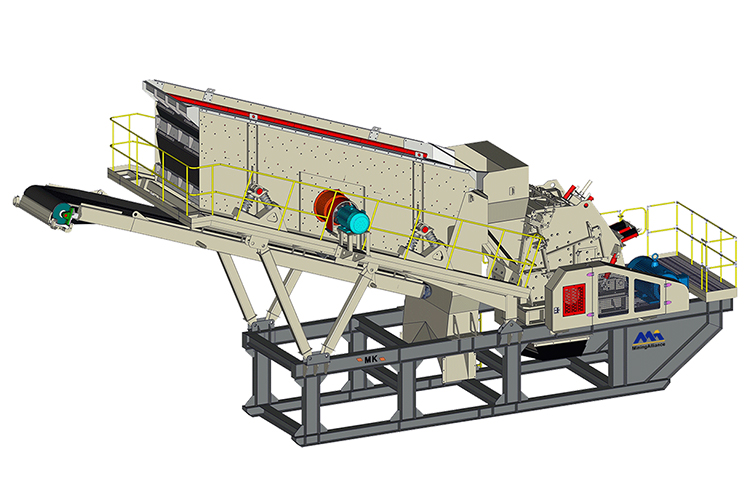

The cone crusher mobile plant is tailored for secondary and tertiary crushing of high-abrasion materials. Featuring a reliable cone crushing unit, it excels at producing high-quality aggregates from granite, quartzite, and iron ore.

Its hydraulic drive and intelligent control systems allow precise adjustment of the closed side setting (CSS), ensuring product size consistency. Combined with automated overload protection and lubrication monitoring, it minimizes wear and downtime.

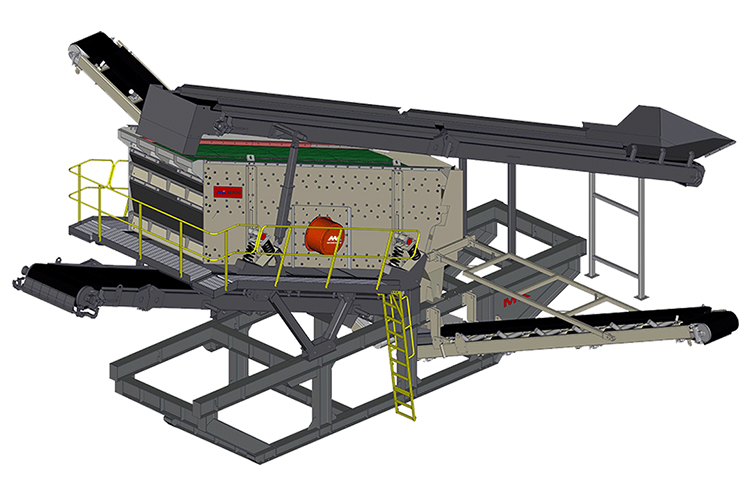

Ideal for mining operations and large-scale infrastructure projects, the cone crusher mobile plant supports high production rates with reduced operating costs. Its mobility enhances adaptability to changing site needs, ensuring productivity without sacrificing quality.

The integration of heavy-duty screens and advanced feed control systems ensures optimal material flow and uniform load distribution across the crushing chamber. These features lead to consistent performance, even in the toughest working conditions.

Cone mobile units often include onboard diesel-electric hybrid systems, allowing for fuel efficiency and reduced environmental impact. Operators can expect quiet, low-emission operation suitable for urban and environmentally sensitive areas.

In multi-stage crushing applications, the cone crusher mobile plant seamlessly interfaces with jaw and impact units, forming an integrated and highly efficient portable crushing circuit.