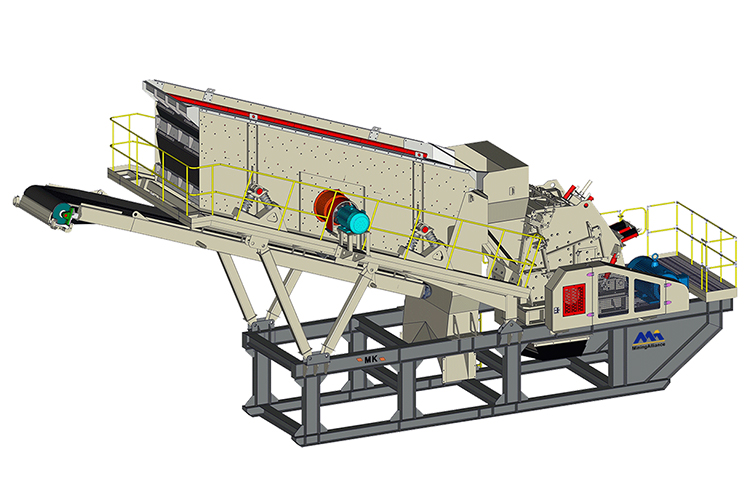

Jaw crusher mobile plants combine the proven strength of jaw crushing with the flexibility of mobile systems. Built for processing tough rock in construction, mining, and demolition applications, these mobile units are designed for mobility without compromising on power or durability.

Equipped with a heavy-duty jaw crusher, a mobile chassis, and optional onboard generators, the unit can operate in remote locations without external power. Its high crushing ratio and robust feed capacity make it suitable for hard materials like granite, basalt, and recycled concrete.

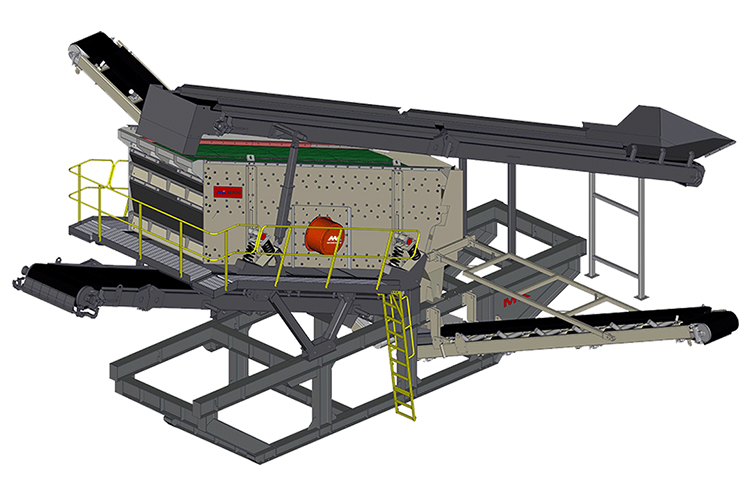

The mobile platform allows for quick setup and relocation, enabling operators to reduce downtime and transportation costs. Advanced control systems, hydraulic adjustments, and dust suppression equipment make this a modern solution for primary crushing in mobile scenarios.

What sets the jaw crusher mobile plant apart is its compatibility with various feed materials and job sites. From urban demolition projects to rural mining operations, the adaptability and compact footprint of the unit ensure minimal site preparation. Operators benefit from low fuel consumption and simplified maintenance protocols, thanks to durable components and modular engineering.

Moreover, integrated telematics and GPS tracking allow fleet managers to monitor real-time performance, location, and maintenance needs remotely. The plant’s rugged build and high-throughput performance make it a long-term investment for enterprises aiming to boost productivity in dynamic environments.