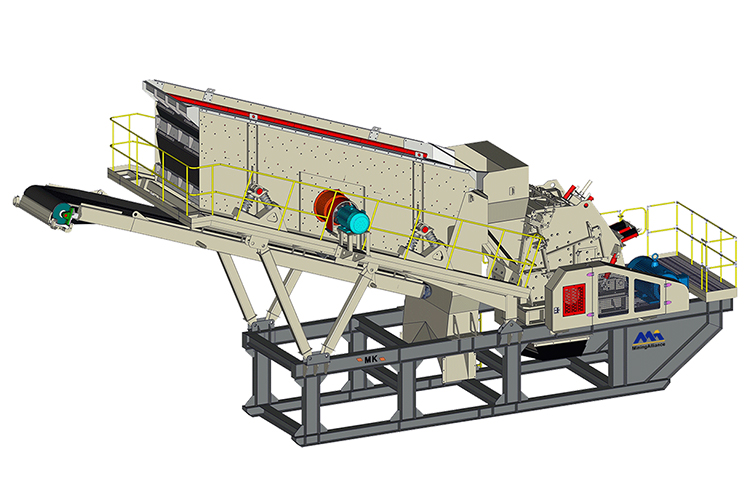

Mobile crushing and screening stations integrate primary crushing, secondary crushing, and screening functions on a single platform. These stations offer full-process handling of materials from feed to final classification, making them highly efficient for temporary or rapidly changing work sites.

With customizable configurations using jaw, impact, or cone crushers paired with vibrating screens, the system handles everything from raw rock to finished aggregate. Its automated control systems enable real-time performance monitoring and operational adjustments.

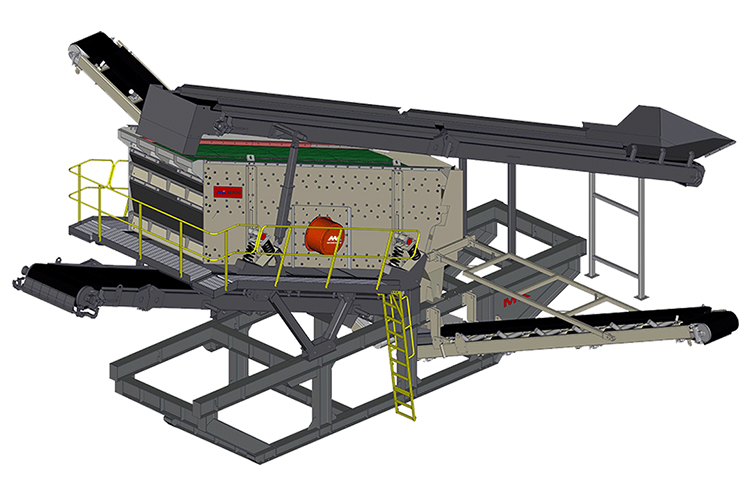

Designed for urban construction, highway projects, and recycling yards, these stations reduce the need for multiple machines and associated logistics. Compact, efficient, and environmentally conscious, the mobile crushing and screening station is redefining jobsite productivity.

New-generation units offer hybrid power options, allowing seamless switching between diesel and electric modes based on job site conditions. This not only conserves energy but also aligns with evolving global sustainability standards.

Anti-dust enclosures, onboard water sprays, and intelligent load-sensing conveyors further enhance environmental compliance. The intuitive HMI interfaces provide operators with detailed diagnostics and operational statistics, improving uptime and resource planning.

Mobile crushing and screening stations are a smart investment for contractors seeking scalable, high-throughput processing without compromising agility or environmental responsibility.