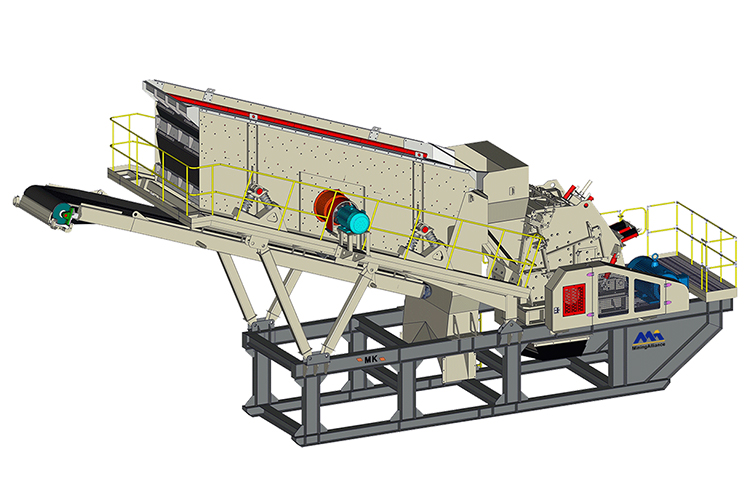

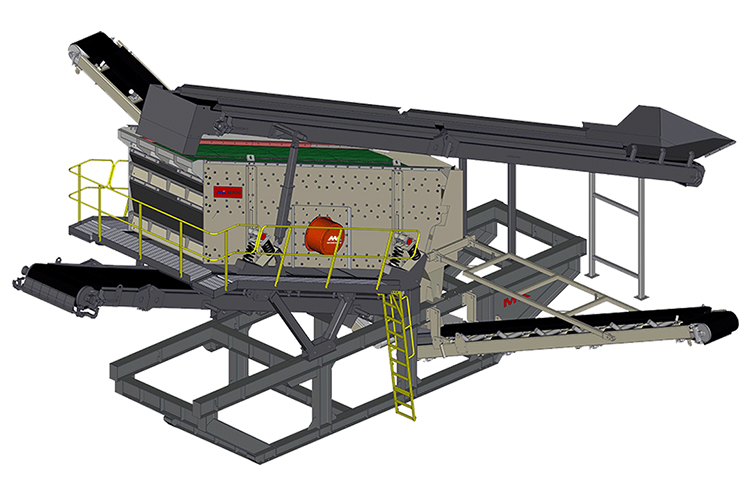

The 300TPH mobile crushing plant is an efficient integrated unit combining crushing, screening, and conveying. With features such as flexibility, stable capacity, and strong adaptability, it can operate smoothly under various working conditions, meeting the demand for aggregates across multiple industries.

In metal and non-metal mining operations, the mobile crushing plant can work directly at mining sites, significantly reducing material transportation costs. Its efficient crushing ability meets both primary and secondary crushing requirements.

During urban renovation and demolition projects, the mobile crushing plant processes concrete, bricks, and stones from construction waste into reusable aggregates, which can be applied in road base layers and concrete production, promoting recycling and sustainability.

Large-scale projects such as highways, railways, hydropower, and port construction require massive amounts of aggregates. The mobile crushing plant can produce aggregates directly on-site, ensuring timely supply, reducing transportation costs, and shortening construction periods.

In quarries and aggregate plants, the mobile crushing plant, with its mobility and quick setup, can shift operations between different sites efficiently, meeting diverse production needs and improving overall productivity.

With advantages of efficiency, eco-friendliness, and mobility, the 300TPH mobile crushing plant is widely applied in mining, construction waste recycling, infrastructure projects, and quarrying. It not only boosts aggregate production efficiency but also contributes to resource conservation and sustainable development.