Sand and aggregates are among the most essential raw materials in infrastructure construction, widely used in roads, highways, railways, bridges, real estate, and municipal projects. High-quality sand and aggregate production relies heavily on advanced and efficient equipment. This article introduces the key equipment applied in sand and aggregate production lines.

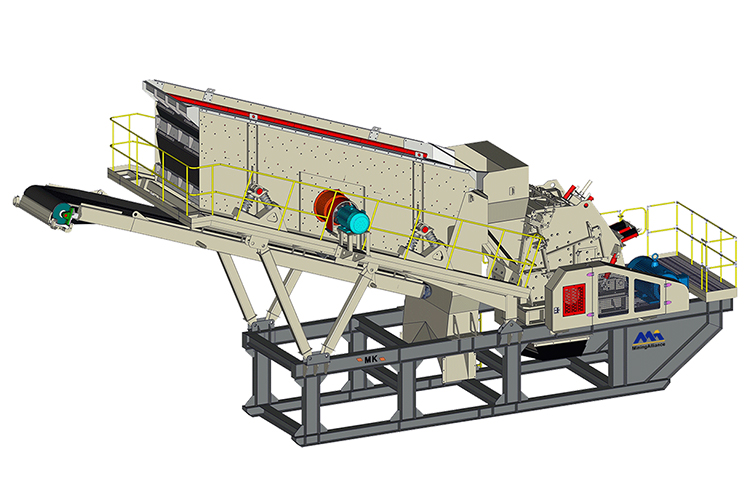

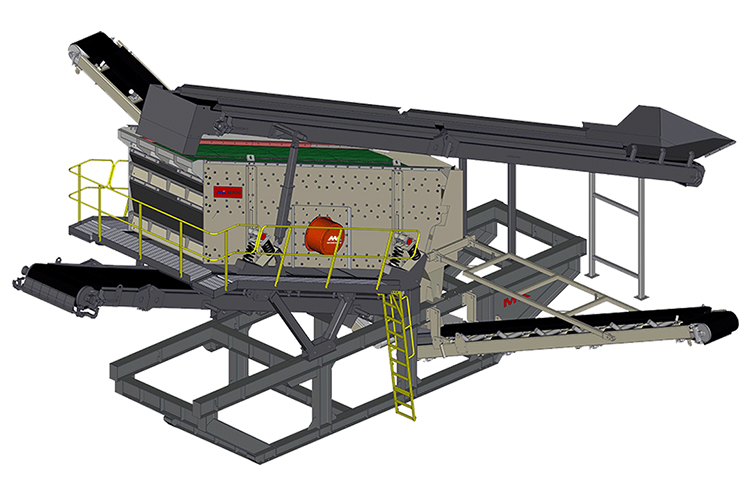

In sand and aggregate production, crushing equipment is the core component. Common machines include jaw crushers, cone crushers, impact crushers, and mobile crushing plants.

- Jaw Crusher: Mainly used for primary crushing, breaking large stones into smaller sizes.

- Cone Crusher: Applied for secondary and fine crushing, especially suitable for hard rock and abrasive materials.

- Mobile Crushing Plant: Flexible and relocatable, ideal for complex sites and construction waste recycling.

Screening machines are used to classify crushed materials by size, ensuring uniform particle shape and proper gradation of the final product. Vibrating screens, in particular, are widely applied due to their high screening efficiency and large handling capacity, making them indispensable in sand and aggregate production.

Sand-making machines (such as VSI impact crushers) are crucial for processing aggregates into manufactured sand. They produce sand with excellent shape and reasonable gradation, making them widely used in concrete and mortar production.

Conveyors ensure continuous material flow within the production line, improving overall efficiency. Sand washing machines clean impurities and silt from the final sand and aggregate, enhancing quality to meet high construction standards.

Sand and aggregate production is a systematic process, where each stage—crushing, screening, sand-making, and washing—requires advanced equipment. Our company is committed to providing customers with integrated sand and aggregate production solutions, helping them achieve efficient, eco-friendly, and intelligent operations.