In a coastal industrial area, large quantities of basalt-slag (a by-product generated during metal smelting and high-temperature processing of basalt-rich ores) had accumulated over the years. These slag piles not only occupied valuable land resources but also imposed environmental burdens and high transportation costs. The client sought an efficient and sustainable solution to convert this slag into reusable construction materials.

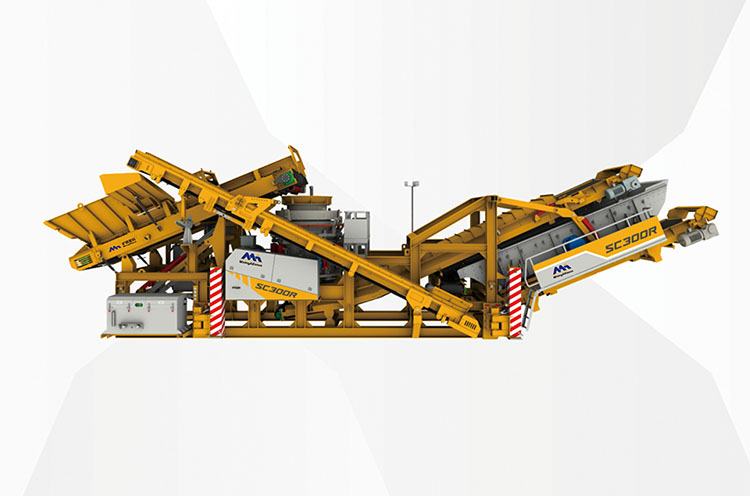

Given the limited site space, tight project schedule, and the high hardness of the raw material, the customer chose to work with our company to implement a portable / semi-mobile crushing and screening system. This approach enabled rapid deployment, minimized civil engineering work, and ensured efficient material processing under strict environmental requirements.

Project Objectives

Before designing the solution, the client defined several key objectives. Convert waste basalt slag into high-value aggregates. Ensure stable and efficient production in a confined working area. Reduce civil construction investment with a modular, quickly deployable system. Maintain strict control of dust and noise emissions. Achieve fast installation, commissioning, and long-term reliable operation

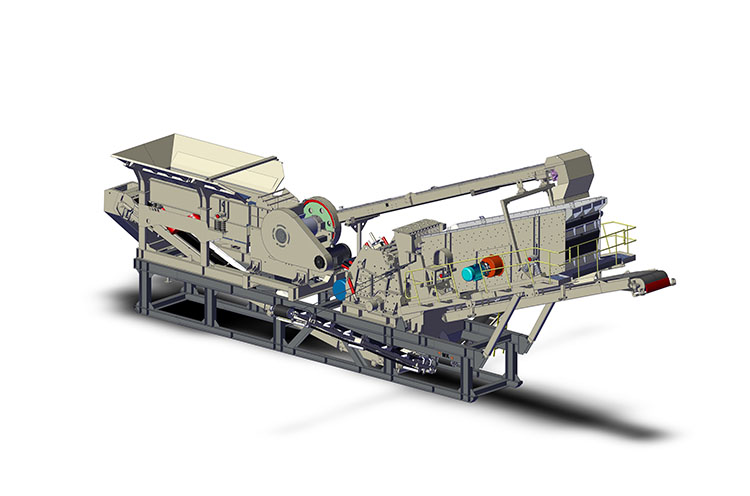

Our engineering team proposed a complete portable crushing and screening solution tailored to the customer’s operational needs and raw material characteristics.

Equipment Configuration

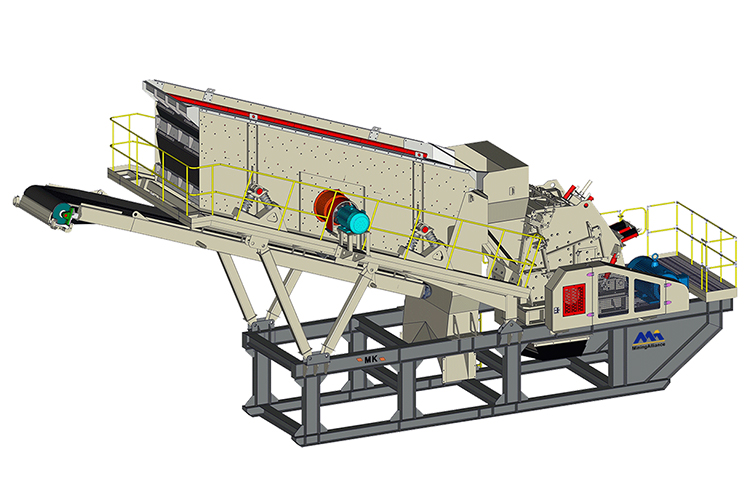

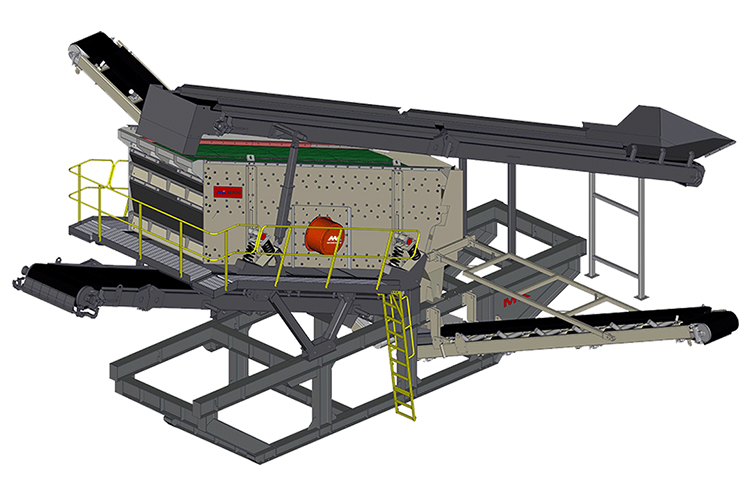

To handle the high hardness and irregular nature of basalt slag, the project adopted the following core equipment. All modules can be lifted and transported as integrated units, significantly reducing installation time.

- C6X Jaw Crusher

For primary crushing of large and abrasive slag blocks - CS / HPT Cone Crusher

For secondary and tertiary crushing, producing well-shaped aggregates - SL Linear Vibrating Screen

For fine screening and multi-grade product separation - Modular Semi-Mobile (Skid-Mounted) Crusher & Screening Modules

For quick mobility and minimized civil work - Belt Conveying System

For efficient transfer of materials between different processing sections

Project Advantages

The project site was narrow and restricted due to nearby water channels. To address this, a "C-shaped" configuration was designed—enabling each processing module to align effectively while ensuring smooth material flow. This not only optimized space usage but also reduced civil works.

The semi-mobile modules can be delivered, lifted, installed, and commissioned in a matter of 12–48 hours. This rapid deployment significantly shortens the construction cycle, enabling the client to begin production almost immediately after delivery.

Basalt slag is known for its high hardness and variability. The combination of jaw crushing, cone crushing, and fine screening ensures consistent production and high wear resistance, making the entire system suitable for processing slag, basalt, and other hard rock materials.

Suitable as base material for highways, railways, and urban roads. High-strength aggregates produced from the slag are ideal for use in structural concrete. The material’s hardness and durability make it suitable for coastal and hydraulic construction. Recycling slag aligns with global trends in resource conservation and circular economy practices.

This Basalt Slag Portable Crushing & Screening Plant project represents an important achievement in industrial waste reuse. Through modular design, rapid installation, efficient crushing technology, and environmental enhancements, our solution successfully transformed difficult-to-handle slag into valuable construction aggregates.