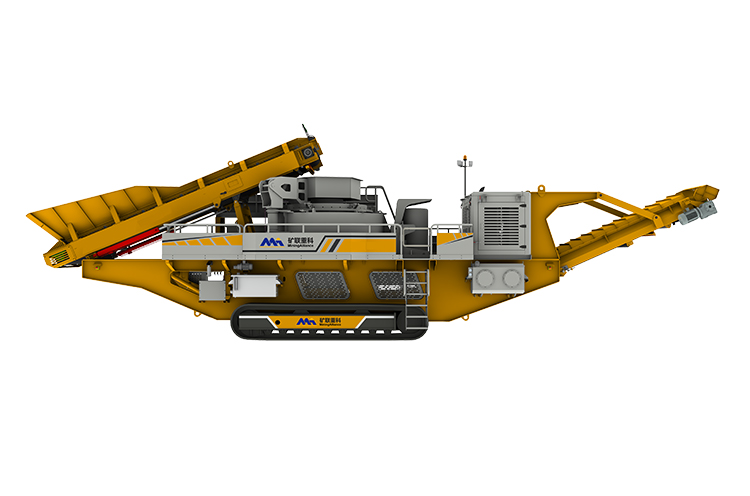

In southern Mongolia, we delivered a 120t/h tire-type mobile crushing station for aggregate production from hard rock and limestone. Mongolia’s complex terrain and cold, arid climate, along with widely distributed mining sites, make traditional fixed crushing equipment difficult to deploy flexibly. The tire-type mobile crushing station, with its modular design and rapid relocation capability, can quickly enter mining sites and perform crushing operations on-site, significantly reducing project timelines.

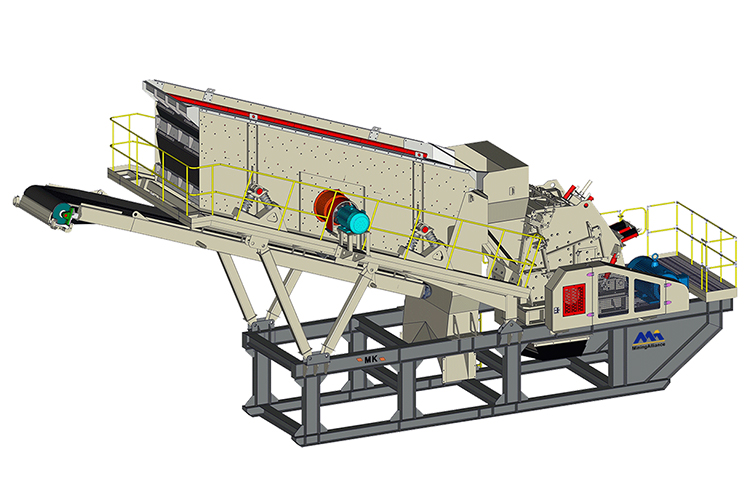

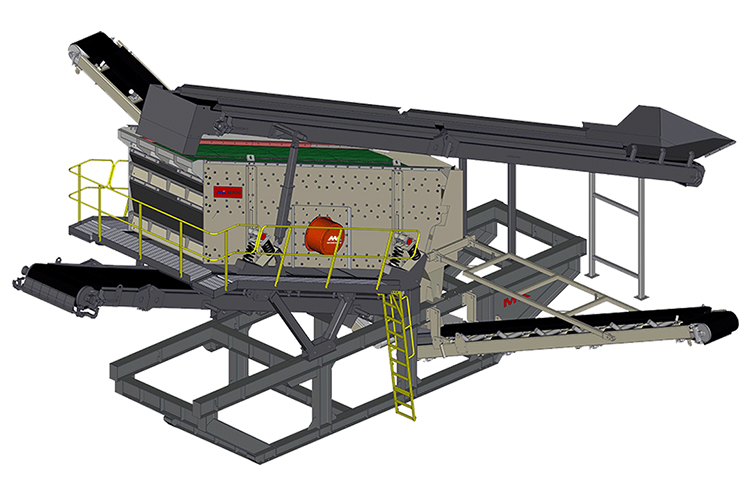

The equipment configuration is flexible: a jaw crusher performs primary crushing for large rocks, followed by an impact or cone crusher for secondary and tertiary crushing, ensuring uniform particle size that meets road and concrete construction standards. A vibrating screen provides multi-level grading, while conveyors link the system for automated continuous production. Operators can monitor operational status and adjust output and material flow remotely via the intelligent control system, enhancing convenience and safety.

Field results show a daily output exceeding 120t of high-quality aggregates, supplying raw materials for road construction and infrastructure projects. Wear parts are made of high-performance materials, maintaining high stability and long service life even under high-hardness rock crushing conditions. The flexibility of the tire-type mobile crushing station reduces transport and labor costs, improves site efficiency, and lowers operational risks.

The successful implementation of this project demonstrates the high adaptability of tire-type mobile crushing stations in complex terrains, high-hardness ores, and cold, arid conditions, providing a reliable solution for infrastructure development in Mongolia and surrounding regions.