In central Kazakhstan, we deployed a 250t/h tracked mobile crushing station for granite and volcanic rock aggregate production. The rugged terrain and limited transport options in Kazakhstan make fixed crushing equipment difficult to deliver. The tracked mobile crushing station can access the mining site directly, enabling rapid installation and commissioning, reducing pre-construction preparation time.

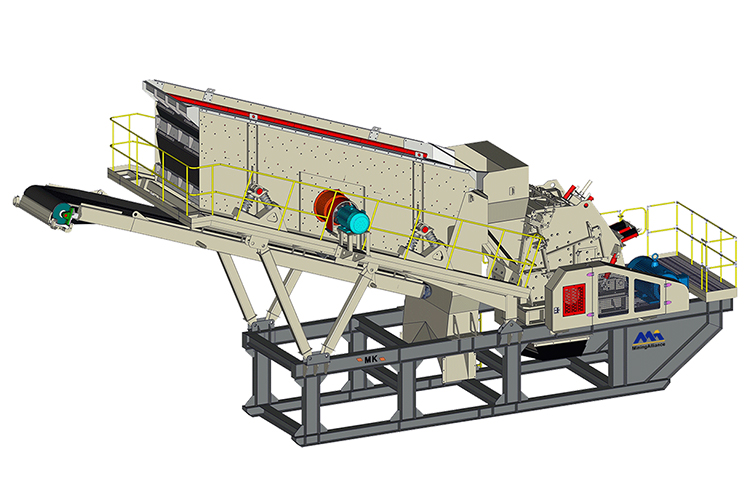

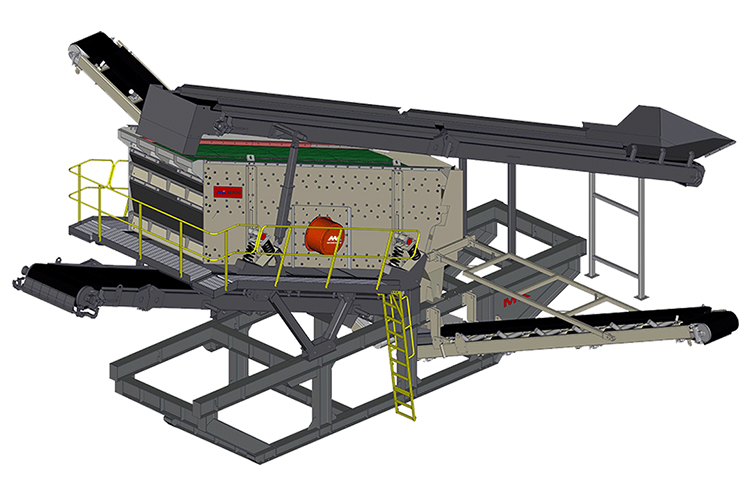

The tracked chassis ensures stability on steep slopes and rocky terrain. The equipment configuration includes a jaw crusher, cone crusher, and impact crusher, handling primary, secondary, and tertiary crushing. Vibrating screens and conveyor systems enable automatic grading and continuous transport, efficiently moving material from crushing to stockpiling.

An intelligent control system allows operators to remotely adjust parameters, monitor production, and troubleshoot issues in real-time, ensuring site safety. Optimized wear-resistant materials keep the equipment stable and reliable under continuous high-load operations, reducing maintenance frequency and operating costs. Field tests show a daily output of 250t of high-quality aggregates, widely used for road construction, concrete production, and large-scale building projects.

The successful operation of this project not only improves production efficiency in Kazakhstan mining sites but also provides a reference for projects in similar terrains and ore conditions. The flexibility, high output, and reliability of tracked mobile crushing stations make them an ideal choice for large-scale mines and infrastructure projects.