With the continuous advancement of infrastructure construction, the demand for sand and aggregate keeps increasing, while projects place higher requirements on construction schedules, environmental protection, and cost control. Under this background, mobile crushing stations, featuring flexibility, high efficiency, and integrated design, have gradually become essential equipment in aggregate production and mining operations.

With the continuous advancement of infrastructure construction, the demand for sand and aggregate keeps increasing, while projects place higher requirements on construction schedules, environmental protection, and cost control. Under this background, mobile crushing stations, featuring flexibility, high efficiency, and integrated design, have gradually become essential equipment in aggregate production and mining operations.

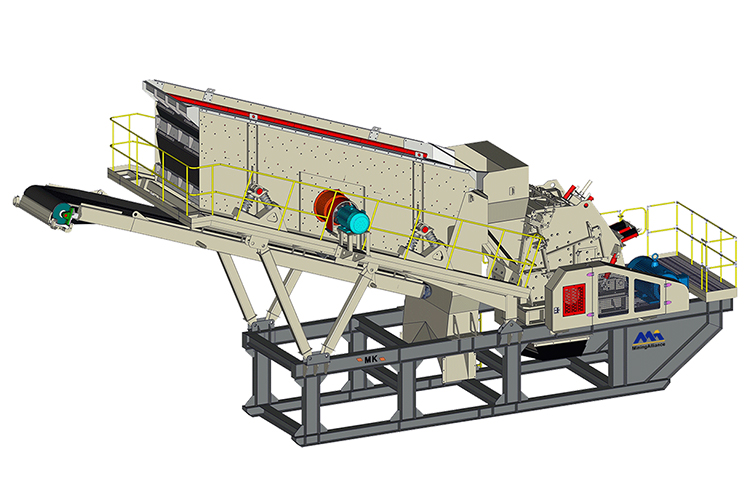

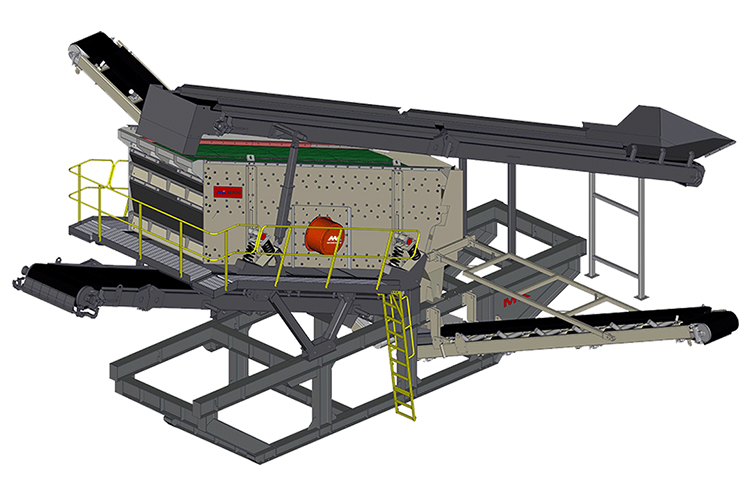

A mobile crushing station integrates feeding, crushing, screening, and conveying processes into a single movable platform. According to production requirements, it can be flexibly equipped with jaw crushers, impact crushers, cone crushers, or sand-making machines, enabling integrated operations from primary crushing to secondary, tertiary crushing, and even sand production. Compared with traditional stationary production lines, mobile crushing stations require no complicated civil foundation and can be put into operation quickly after arrival on site, significantly shortening the project construction period.

During aggregate production, mobile crushing stations can operate close to raw material stockpiles or mining faces, reducing secondary transportation distances and effectively lowering fuel consumption and transportation costs. For mountainous areas, scattered quarry sites, or temporary projects, the mobility advantage of the equipment is particularly significant. In addition, the modular design allows for easy relocation, enabling flexible adjustment of working positions as mining progresses and improving overall equipment utilization.