Basalt is a hard and dense volcanic rock that is widely used in road construction, railway ballast, concrete aggregates, and infrastructure projects. Due to its high compressive strength and strong abrasiveness, basalt places higher demands on crushing equipment in terms of stability, wear resistance, and continuous operating capability.

To meet these requirements, a 100 TPH Mobile Basalt Crushing Production Line was developed to provide a practical and flexible solution for medium-scale aggregate production.

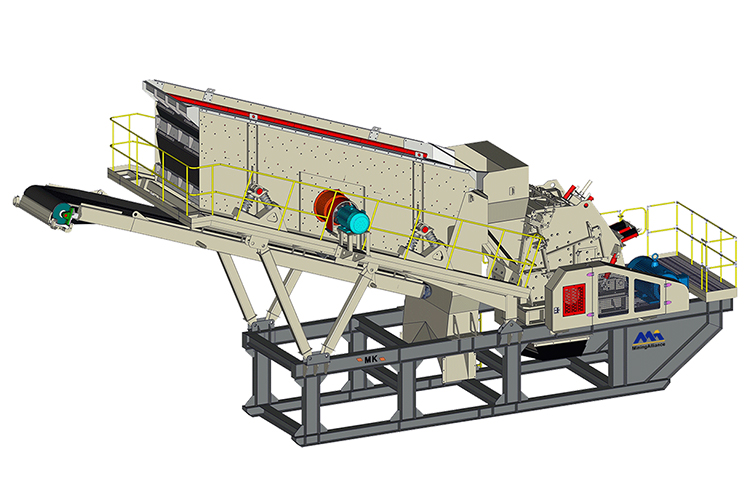

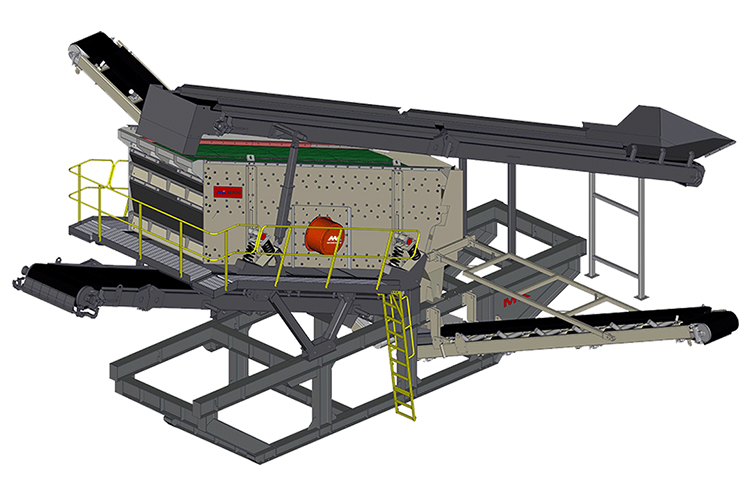

This mobile crushing production line is designed with a rated capacity of approximately 100 tons per hour, suitable for on-site processing of basalt in quarries, infrastructure projects, and temporary construction sites. The system integrates feeding, crushing, screening, and conveying into a compact mobile structure, allowing the entire line to operate independently without complex civil foundations.

The mobile layout enables the equipment to be deployed close to the raw material source, reducing material transport distances and improving overall operational efficiency.

With optimized crushing chambers and reasonable equipment matching, the line can continuously produce standard basalt aggregates such as 0–5 mm, 5–10 mm, and 10–20 mm. The finished products show good particle shape and low flakiness content, meeting the quality requirements of concrete batching plants and road construction projects.

The system allows flexible adjustment of discharge settings to adapt to different material conditions and product specifications.

One of the main advantages of this mobile crushing line is its mobility. Compared with stationary plants, it requires minimal site preparation and can be put into operation in a short time. When the working face changes, the equipment can be relocated quickly, making it especially suitable for:

- Mountainous quarry areas

- Scattered or limited production sites

- Short-term or phased construction projects

Environmental and Operational Consideration

The mobile basalt crushing line is equipped with dust suppression and noise reduction measures to meet common environmental requirements. Key wear parts are manufactured from high-strength, wear-resistant materials, ensuring reliable performance under long-term crushing of hard basalt.

Simple control systems and clear equipment layout make daily operation and maintenance more convenient, helping reduce downtime and operating costs.

The 100 TPH Mobile Basalt Crushing Production Line offers a balanced solution for basalt aggregate production, combining stable output, flexible deployment, and practical operation. Its mobile design reduces construction investment and improves site adaptability, making it a reliable option for contractors and quarry operators seeking efficient hard-rock crushing solutions.