Understand Your Project Requirements

Before comparing crusher models or manufacturers, it is essential to clearly define what your project needs. The nature of the material, required output size, and production capacity all play a decisive role in selecting the most suitable mobile crusher.

Type of Material to Be Crushed

Different materials behave very differently during crushing, and choosing the wrong crusher type can lead to excessive wear, poor output quality, or frequent downtime.

Hard Rock (Granite, Basalt)

Hard and abrasive rocks such as granite and basalt require robust crushing equipment with high compressive strength. These materials cause significant wear on crusher components, making durability and wear-resistant parts essential. Crushers designed for hard rock typically operate at lower reduction ratios but offer higher reliability and longer service life.

Soft Rock (Limestone)

Limestone and other soft to medium-hard rocks are easier to crush and allow for greater flexibility in crusher selection. Impact crushers are often preferred for limestone due to their ability to produce a well-shaped final product, while jaw crushers can still be used effectively for primary crushing.

Recycled Materials (Concrete, Asphalt, Bricks)

Recycling applications demand crushers that can handle variable feed materials, embedded steel, and contaminants. Impact crushers are commonly used because they can efficiently process concrete and asphalt while producing high-quality recycled aggregates. Jaw crushers are also used in primary stages for processing large demolition waste.

Moist or Sticky Materials

Materials with high moisture content or clay can clog certain crusher types, especially impact crushers with closed rotor designs. For these applications, crushers with open designs, high clearance, and effective material flow are preferable to prevent blockages and maintain consistent output.

Impact of Material Properties on Crusher Choice

- Hardness influences the required crushing force and wear resistance.

- Abrasiveness determines the lifespan of liners, jaws, and mantles.

- Feed size affects whether primary crushing is needed and the size of the crusher opening.

Understanding these characteristics ensures that the selected crusher can handle the material efficiently and economically.

Required Output Size and Capacity

Your desired product size and production volume are equally important considerations.

Desired final product size:

Depending on the end use—whether road base, concrete aggregate, or fine sand—you must match crusher settings and types to achieve the required gradation. Jaw crushers typically produce coarser output, while cone and impact crushers offer finer, more uniformly shaped aggregates.

Throughput (tons per hour):

Projects with high output demands, such as large-scale quarrying operations, require crushers that can handle continuous high tonnage—often in the range of 200–500 tons per hour. Smaller recycling or construction sites may only need 50–150 tons per hour, allowing for more compact machines.

Single vs. multi-stage crushing setups:

In single-stage crushing, one crusher carries out all the reduction. This setup is cost-effective for smaller or less demanding jobs. Multi-stage setups—typically combining jaw, cone, and/or impact crushers—allow for greater control over particle size and shape, ideal for high-spec aggregate or multiple product outputs.

Types of Mobile Crushers

Mobile crushers are designed to provide flexibility, mobility, and efficiency on site. The three most common types are jaw crushers, impact crushers, and cone crushers, each serving a specific role in the crushing process.

2.1 Mobile Jaw Crushers

Mobile jaw crushers are most commonly used for primary crushing and are known for their ability to handle large and hard materials.

Best for Primary Crushing

Jaw crushers use compressive force to break material between a fixed and a moving jaw. This simple but powerful mechanism makes them ideal for reducing large feed sizes into manageable output for secondary crushers.

Suitable for Hard and Large Materials

These crushers perform well with hard rock, blasted stone, and concrete debris. Their robust design allows them to withstand heavy loads and tough operating conditions.

2.2 Mobile Impact Crushers

Mobile impact crushers use high-speed impact force to break material, making them especially popular in recycling and soft-rock applications.

Ideal for Recycling and Softer Materials

Impact crushers excel in processing limestone, concrete, asphalt, and demolition waste. They can break material along natural fracture lines, resulting in cleaner separation.

Produces Well-Shaped Aggregates

One of the key advantages of impact crushers is their ability to produce cubical, well-graded aggregates, which are highly desirable for concrete and asphalt applications.

2.3 Mobile Cone Crushers

Mobile cone crushers are typically used in secondary and tertiary crushing stages where precision and consistency are required.

Used for Secondary and Tertiary Crushing

Cone crushers operate by compressing material between a rotating mantle and a concave bowl. This allows for controlled crushing and consistent output size.

High-Quality, Uniform Output

These crushers are known for producing uniform, high-quality aggregates suitable for demanding applications such as high-strength concrete and asphalt mixes.

Suitable for Hard and Abrasive Materials

Cone crushers perform exceptionally well with hard and abrasive rocks, offering lower wear costs compared to impact crushers in these conditions.

Manufacturer Reputation and After-Sales Support

Beyond technical specifications, the choice of manufacturer plays a vital role in long-term project success.

Brand Reliability and Market Experience

Established manufacturers with proven track records are more likely to deliver reliable machines that perform as expected. Experience in different applications and environments often translates into better design, testing, and innovation.

Availability of Spare Parts

Quick access to spare and wear parts is essential to minimize downtime. Manufacturers with global distribution networks and local inventory can significantly reduce maintenance delays and operating costs.

Right Mobile Crusher Manufacturer for Your Project

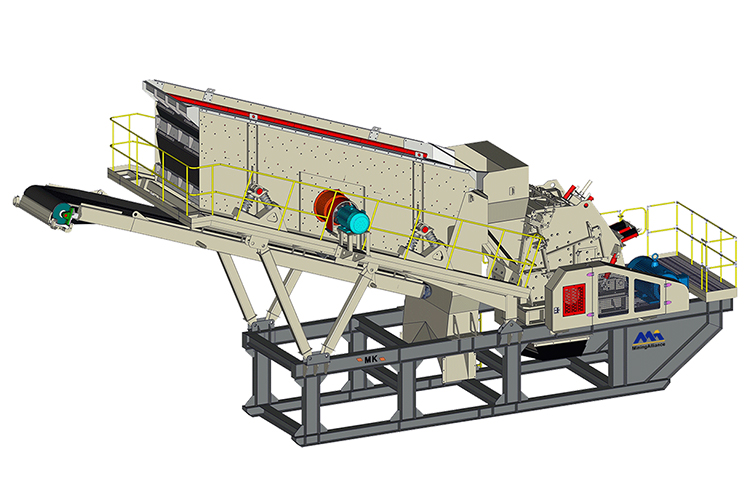

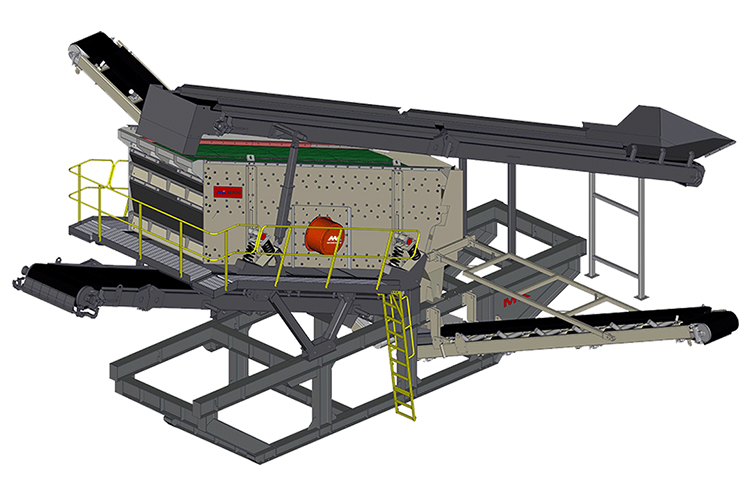

MiningAlliance positions itself between large Chinese manufacturers and international brands.

Rather than competing on scale or brand history, it focuses on project-based mobile crushing solutions, especially for tracked mobile crushers, tire mobile crushers, and mini mobile crushers used in small to mid-scale projects.

For 5–300 TPH projects, international brands are not always necessary.

Many buyers choose specialized Chinese suppliers like MiningAlliance, which focus on this capacity range and provide customized tracked, wheeled, or mini mobile crushing solutions with more reasonable investment levels.