In Malaysia, marble is not only valued as a premium decorative stone, but when finely crushed and processed, it also serves as an excellent raw material for high-quality construction aggregates and manufactured sand. For a client whose raw material is high-hardness marble, we designed and commissioned a 100 tons per hour (TPH) mobile crushing, screening, and sand making plant, delivering efficient, eco-friendly, and fully integrated production from raw material to finished products.

Project Background

Marble features high density, excellent hardness (Mohs 3–4), and a smooth texture, making it demanding on crushing equipment in terms of wear resistance and operational stability. This project’s equipment configuration and process flow were carefully designed to handle marble’s physical properties, ensuring both capacity and final product quality.

Production Process

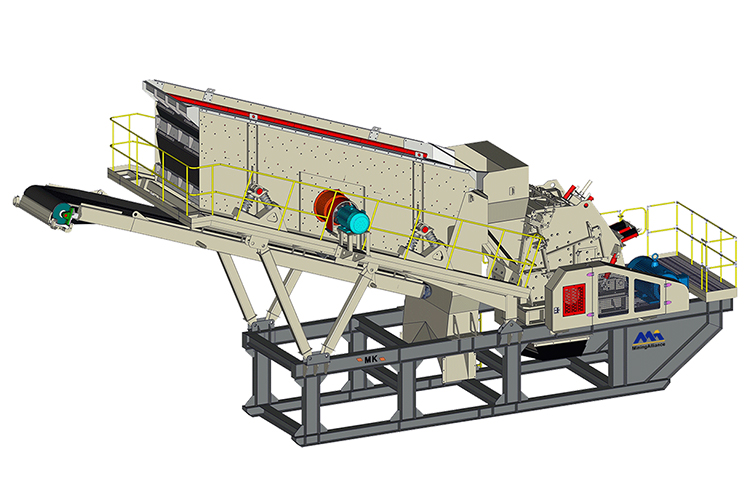

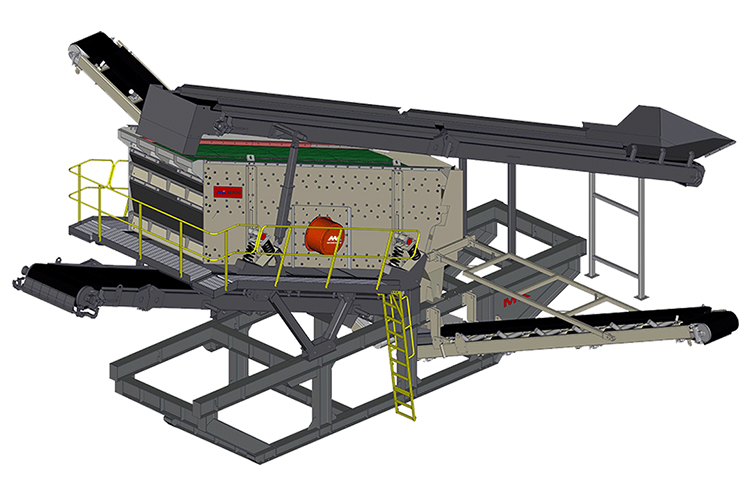

- Primary Crushing, Raw marble is fed into the mobile jaw crusher for the initial crushing stage, reducing large blocks to manageable sizes.

- Secondary Crushing, The material is then processed by the mobile cone crusher for medium and fine crushing, producing well-shaped aggregates while minimizing flaky particles.

- Screening ,The mobile vibrating screen accurately classifies the materials, sending qualified aggregates directly to output, while directing the rest to the sand-making stage.

- Sand Making & Shaping, A high-efficiency sand maker shapes part of the material into premium manufactured sand with excellent particle shape and grading.

- Product Output,Final aggregates and sand of different sizes are stockpiled or loaded for delivery.

Technical Advantages

- Wear-Resistant Design: Crushing chambers, liners, and rotors are made from high wear-resistant materials to withstand marble’s hardness and abrasiveness.

- Stable High Capacity: Mobile plant combined with efficient crushers ensures a consistent 100 TPH output.

- Eco-Friendly Operation: Fully equipped with dust suppression and noise reduction systems, compliant with Malaysia’s environmental standards.

- Versatile Application: Capable of producing both construction aggregates and premium manufactured sand, maximizing raw material utilization.

This plant’s successful operation not only generates significant economic returns for the client but also provides the Malaysian market with a steady supply of high-quality marble aggregates and manufactured sand, supporting the growth of the construction and decorative materials industry.