In the marble mining region of Malaysia, we built a 150 tons per hour aggregate production line for our client, consisting of three mobile crushing plants. Since commissioning, the project has delivered outstanding performance in production efficiency, on-site flexibility, and product quality, becoming a key source of premium aggregates and manufactured sand in the area.

Project Background

Marble, with its high density, moderate hardness (Mohs 3–4), compact texture, and smooth surface, is widely used in architectural decoration and high-end construction projects. When processing marble into aggregates and manufactured sand, equipment must offer excellent wear resistance, operational stability, and superior particle shape. To meet the client’s needs for both high quality and mobility, we adopted a three-unit mobile crushing plant configuration.

Production Process

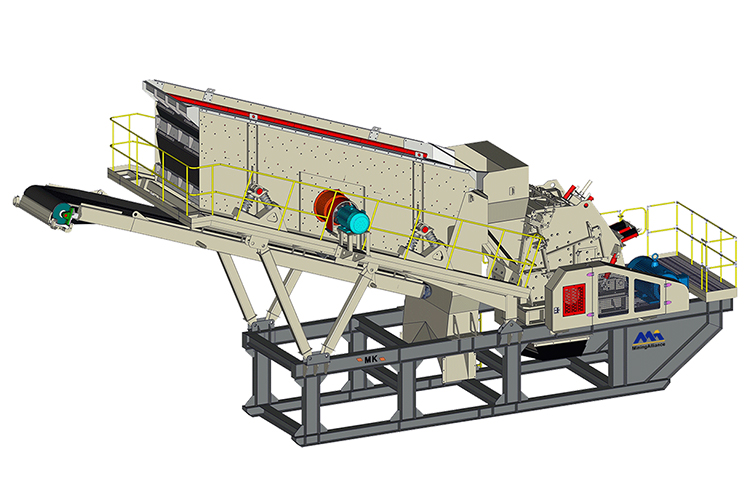

- First Mobile Jaw Crushing Plant

- Role: Primary crushing to reduce large marble blocks to sizes suitable for secondary crushing.

- Advantage: Deep crushing chamber and large feed opening ensure consistent and stable feeding.

- Second Mobile Cone Crushing Plant

- Role: Secondary and fine crushing to improve particle shape and reduce flaky content.

- Advantage: Wear-resistant liners and high-performance hydraulic system handle marble’s abrasiveness effectively.

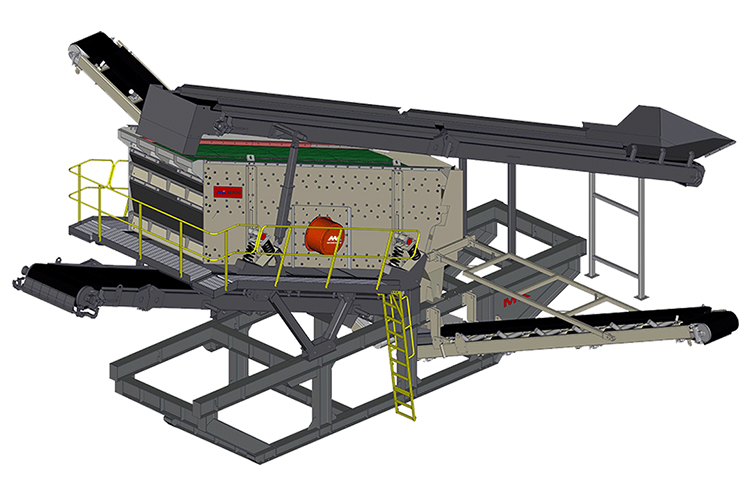

- Third Mobile Screening & Sand Making Plant

- Role: Accurate screening of aggregates into different sizes, and shaping part of the material into manufactured sand.

- Advantage: High screening efficiency, well-shaped sand with excellent grading for high-spec concrete applications.

Project Highlights

- Flexible Operation: Each mobile unit can work independently or in combination, adapting to site and production needs.

- High & Stable Capacity: Consistently delivers 150 TPH, ideal for medium-to-large aggregate projects.

- Eco-Friendly: Equipped with dust suppression and noise reduction systems, fully compliant with Malaysian environmental regulations.

- Multi-Product Output: Produces various aggregate sizes and premium manufactured sand simultaneously, maximizing raw material utilization and profitability.

This production line not only enables the client to maximize the value of their marble resources but also supplies the local construction, road, and high-end engineering sectors with a steady flow of premium aggregates and sand.