Iron ore is one of the most essential raw materials in the steel industry, and its processing quality directly affects the efficiency of smelting and steel production. Traditional fixed crushing plants require long construction periods, occupy large areas, and are difficult to relocate — making them unsuitable for modern mining operations that demand flexibility, energy efficiency, and fast deployment.

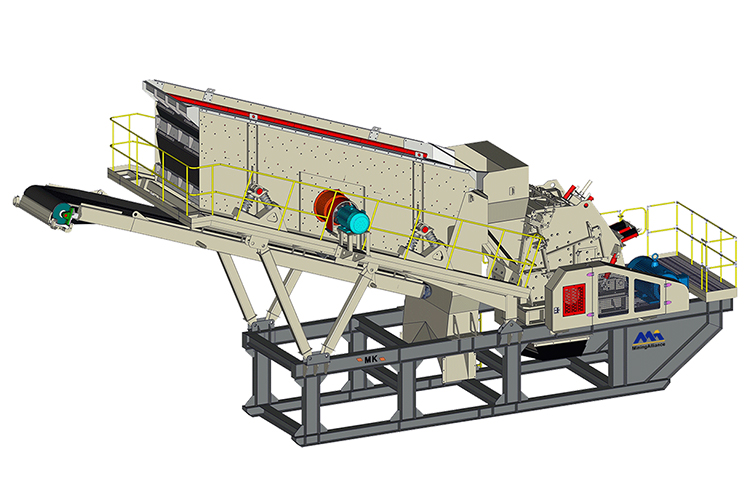

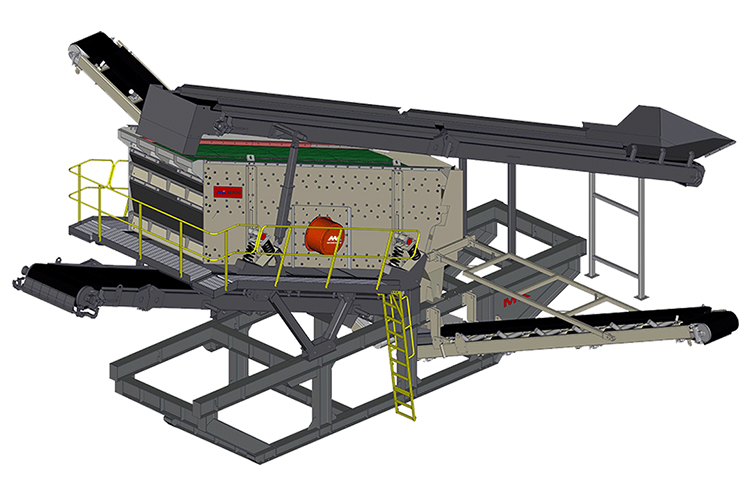

Equipment Overview

The crawler-type mobile plant can be equipped with various crushers — jaw, cone, impact, or VSI — depending on ore characteristics such as magnetite, hematite, or limonite.

- Integrated design combining feeding, crushing, screening, and conveying in one unit.

- Full-crawler drive for stable mobility on complex terrains.

- PLC intelligent control for real-time monitoring and automatic operation.

- Fast setup and relocation, allowing production to start within 24 hours of arrival on site.

Technical Advantages

High Output and Stable Performance

Designed for hard and abrasive iron ore, the main crusher uses heavy-duty wear-resistant components. The intelligent system ensures consistent performance, with capacities ranging from 200–500 TPH.

Excellent Adaptability

The plant performs reliably in open-pit mines, mountain areas, and rough terrain. It can move between mining zones, ensuring flexible operation and maximizing ore utilization.

Energy Efficiency and Environmental Protection

The electric-drive system with variable frequency control reduces energy consumption by about 20% compared to diesel-driven units. Equipped with advanced dust suppression and noise reduction systems, it meets global environmental standards.

Smart Control System

Operators can monitor all parameters — such as production rate, fuel consumption, and maintenance alerts — from a centralized console or mobile device, ensuring safety and efficiency.

Modular and Scalable Design

The plant allows easy configuration changes, enabling multi-stage crushing or different material processing by swapping modules. This flexibility simplifies maintenance and reduces overall operating costs.

Customer Benefits and Performance

In actual projects across South America and Africa, the plant has proven outstanding in both productivity and reliability.

For example, in a Brazilian iron ore site, the equipment has run continuously for over 6,000 hours with downtime under 3%, and the production exceeded design expectations.