A construction company in Oman, Middle East, faced challenges of scattered job sites and frequent but small volumes of construction waste. They deployed multiple wheeled mini crushers to different sites, achieving the goal of "onsite aggregate production and reuse."

Compared with centralized crushing plants, this distributed solution reduced waste transport and secondary pollution. It also brought economic returns—some recycled aggregates were sold to local building material suppliers.

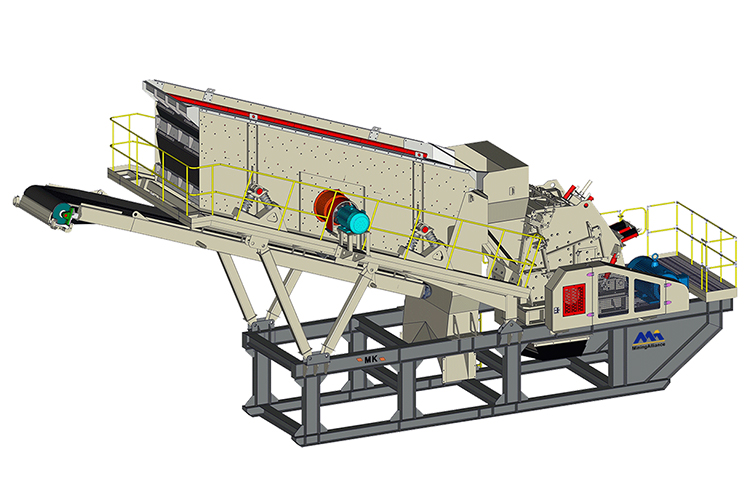

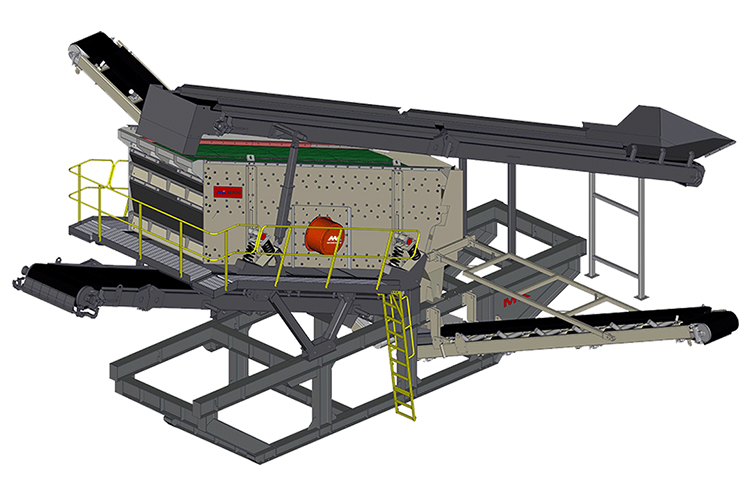

To tackle this issue, the company deployed five wheeled mini crushers, each equipped with diesel engines and basic screening units. These machines independently completed the full process of crushing, screening, and reusing aggregates. Operating in parallel across several districts, they enabled efficient on-site recycling.

Project managers noted that the mini crushers significantly reduced waste transport trips, avoiding traffic congestion and logistical issues. Some recycled materials were even sold to local landscaping firms and concrete batching plants, generating additional revenue.

Project managers noted that the mini crushers significantly reduced waste transport trips, avoiding traffic congestion and logistical issues. Some recycled materials were even sold to local landscaping firms and concrete batching plants, generating additional revenue.