Saudi Arabia has complex geological conditions and is rich in basalt resources, which are ideal materials for producing high-strength construction aggregates. To meet the growing demand for high-quality aggregates in local highways and urban infrastructure projects, our company designed and delivered a 400 TPH basalt mobile crushing and screening production line tailored to the client’s requirements.

Equipment Configuration

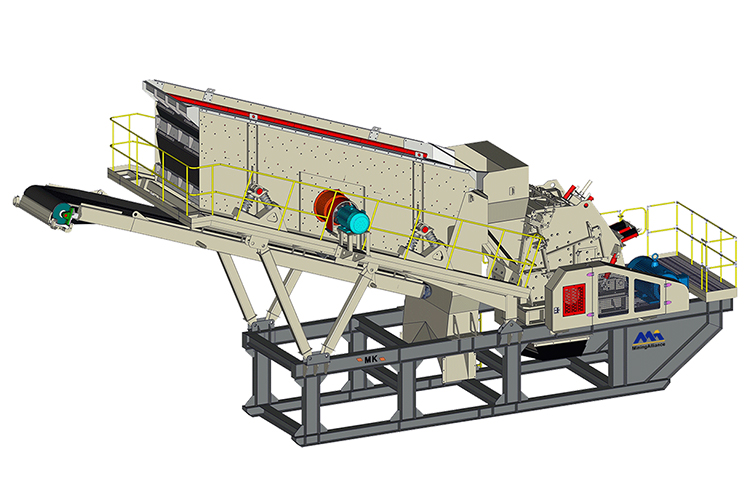

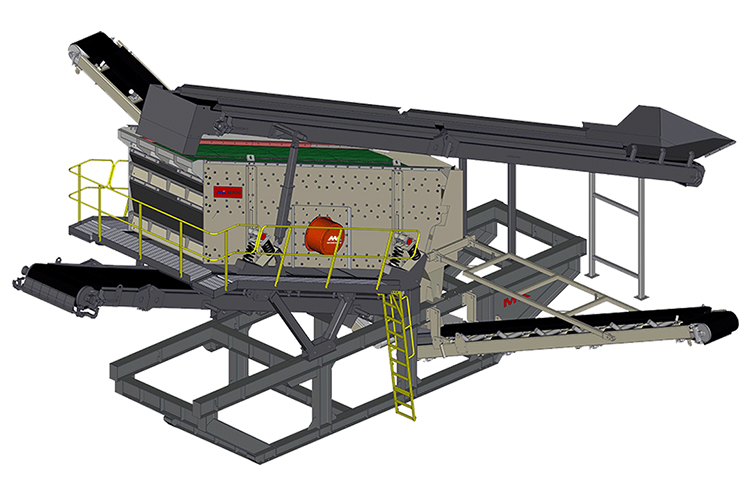

The production line utilizes a combined configuration of tire-type and crawler-type mobile crushing stations, covering four main stages: coarse crushing, fine crushing, screening, and conveying.

Key Features

- Flexible and Mobile: The mobile crushing station can be assembled and commissioned in a short time, allowing easy relocation between project sites, which significantly improves operational efficiency.

- High Efficiency and Energy Saving: Equipped with advanced hydraulic systems and intelligent control technology, ensuring high crushing efficiency, low energy consumption, and stable performance.

- Strong Adaptability and Eco-Friendly Design: The plant is engineered with dustproof and heat-resistant features suitable for Saudi Arabia’s hot and arid climate, ensuring compliance with environmental regulations.

- High-Quality Final Aggregates: The final products feature excellent grain shape and grading, suitable for road pavement, concrete batching, and airport construction projects.

Production Performance

Since commissioning, the production line has been running smoothly with an average output of 400 tons per hour, occasionally peaking at over 420 TPH.

The crushed basalt aggregates have uniform shape and high compressive strength, earning positive feedback from the client. The intelligent monitoring system allows real-time tracking of production data and machine conditions, enhancing management efficiency.

Customer Feedback

The client reported that the mobile crushing production line not only met the project’s high standards for output and particle shape but also greatly reduced site construction and material transport costs. The mobility of the system allowed rapid deployment across different project locations, saving significant time and labor.