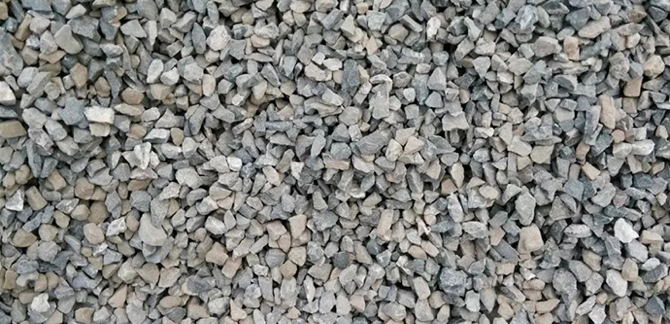

Aggregates are the essential building blocks of modern infrastructure. Used in concrete, asphalt, railways, and foundations, crushed stone and gravel serve as key components in construction and roadwork across the globe. But before these materials can be put to use, they must undergo a systematic process of crushing, screening, and refinement.

This article provides a comprehensive overview of aggregate crushing and processing, explaining the types of materials processed, the stages involved, and the machinery used to produce high-quality construction aggregates.

1. What Is Aggregate?

Aggregate refers to a broad category of coarse to medium-grained particulate materials. It is typically mined from natural sources such as riverbeds, quarries, or rock outcrops and then mechanically crushed and sorted for specific applications.

Common types of aggregates:

- Gravel – Rounded rock, usually from riverbeds

- Crushed stone – Angular rock obtained by mechanically breaking down larger stones

- Sand – Fine aggregate used in concrete and mortar

- Recycled aggregates – Processed construction waste such as crushed concrete or asphalt

2. Importance of Aggregate Processing

Raw materials extracted from nature are often irregular in shape, size, and quality. The crushing and processing of aggregates ensure the production of uniform, graded material suitable for use in:

- Concrete production

- Asphalt paving

- Railway ballast

- Drainage and filtration layers

- Foundation backfill

- Landscaping

High-quality aggregates directly influence the strength, durability, and safety of construction projects.

3. Aggregate Crushing Process: Step-by-Step

The aggregate crushing process typically involves several sequential stages:

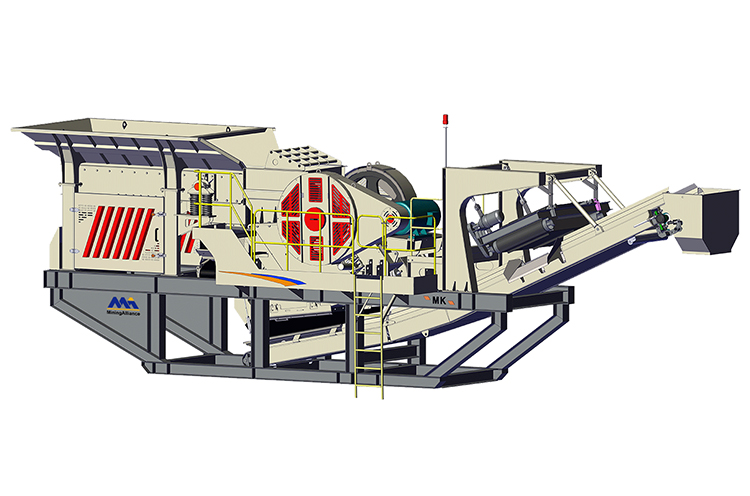

a. Primary Crushing

The first stage involves reducing large rock chunks (up to 1000 mm) into smaller pieces. This is typically achieved using:

- Jaw crushers: Ideal for high-capacity primary crushing

- Gyratory crushers: Used in large-scale mining and quarrying operations

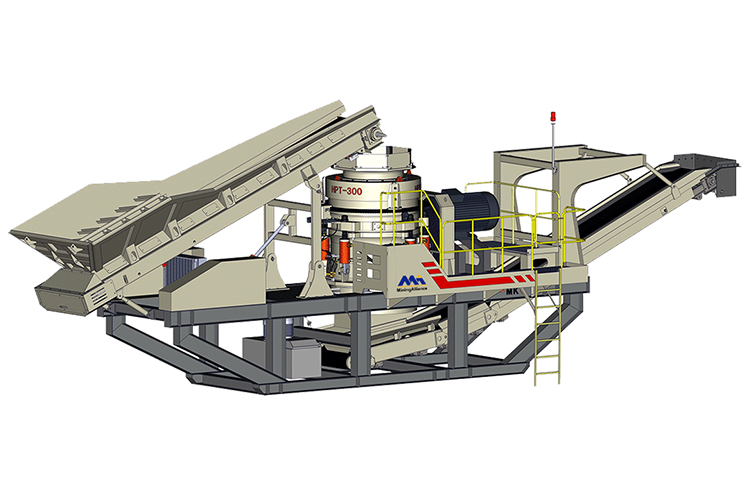

b. Secondary Crushing

Material from the primary crusher is fed into secondary crushers to reduce size further. These include:

- Impact crushers: For medium-hard rock and shaping

- Cone crushers: Ideal for harder materials like granite and basalt

c. Screening

After crushing, the material is screened into different sizes. Vibrating screens are used to separate fine, medium, and coarse aggregates.

d. Tertiary Crushing (if needed)

For high-specification projects, a third stage of crushing may be necessary to refine particle shape and size, especially for road surface layers or decorative stone.

e. Washing and Dewatering

Some aggregates require washing to remove clay, silt, or dust, especially when used for concrete or asphalt. This ensures clean material and better bonding in the final product.

4. Equipment Used in Aggregate Crushing & Processing

A well-designed aggregate crushing plant may consist of:

- Jaw Crusher – For coarse crushing of raw materials

- Cone Crusher – For medium to fine crushing of harder stones

- Impact Crusher – For shaping and producing fine aggregate

- Vibrating Feeder – For controlled feeding of raw materials

- Vibrating Screen – For particle size separation

- Sand Washer – For cleaning fine aggregates

- Belt Conveyors – For material transport between units

- Dust Collectors – For environmental compliance and safety

Modern aggregate plants are often fully automated with PLC control systems, telemetry, and real-time monitoring of performance, vibration, and output.