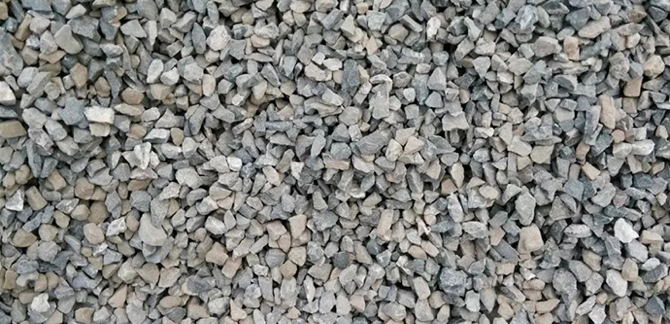

Introduction to Andesite and Its Industrial Uses

Andesite is a fine-grained, intermediate volcanic rock, typically gray in color and found in volcanic regions formed above subduction zones. Due to its high hardness, durability, and resistance to weathering, andesite is widely used in highway construction, railway ballast, concrete aggregate, and building materials. To meet the increasing demand for high-quality aggregates, mobile crushing equipment has become an ideal solution for efficient and flexible andesite processing.

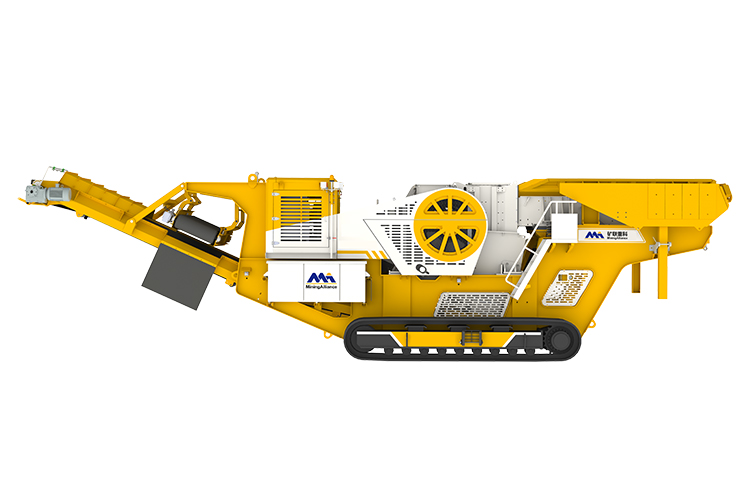

The Advantages of Mobile Crushing Equipment in Andesite Processing

Compared with traditional stationary crushing plants, mobile crushing equipment provides unmatched flexibility and efficiency. It can move freely to different mining sites or construction areas, reducing transportation costs and improving productivity.

Key Advantages:

- High Mobility: The integrated design allows the entire plant to be moved on tracks or wheels, enabling on-site crushing and minimizing material handling.

- Flexible Configuration: Depending on production needs, it can be equipped with jaw crushers, cone crushers, impact crushers, and screening systems to form a complete mobile processing line.

- Quick Installation & Operation: No fixed foundation is needed — plug and play design ensures immediate production after site arrival.

- Low Operating Costs: Reduced logistics, easy maintenance, and intelligent control lower overall operational costs.

Typical Mobile Crushing Process for Andesite

A typical andesite mobile crushing plant includes multiple modules working in synergy:

- Primary Crushing (Mobile Jaw Crusher): The raw andesite is fed into the mobile jaw crusher for coarse crushing, producing uniform feed material for secondary crushing.

- Secondary Crushing (Mobile Cone or Impact Crusher): Depending on the material hardness and final product requirements, cone or impact crushers are used for medium and fine crushing.

- Screening and Conveying: The crushed materials are screened into different size ranges by a mobile vibrating screen, and qualified products are directly transported for use.

The entire process is efficient, clean, and continuous, ensuring consistent product quality and stable output.

Features of Modern Mobile Crushing Equipment

Modern mobile crushing plants are designed with advanced technology and intelligent systems, making them suitable for even the toughest working environments.

- Stable Performance: Heavy-duty chassis and hydraulic systems ensure reliable operation under harsh conditions.

- Energy Efficiency: Intelligent control optimizes crusher load and power usage.

- Environmental Protection: Dust suppression, noise control, and eco-friendly design reduce environmental impact.

- Ease of Maintenance: Modular structure and automatic lubrication simplify maintenance and extend lifespan.

Application Fields and Case Studies

Mobile crushing equipment has been successfully applied in andesite quarries, infrastructure construction, and mining projects across Asia, South America, and Africa.

For instance, in Indonesia where andesite is abundant mobile crushing plants are used to produce high-quality aggregates for expressways and hydropower projects. Their mobility allows them to move between quarries easily, ensuring continuous material supply.