Introduction to Dolomite and Its Industrial Uses

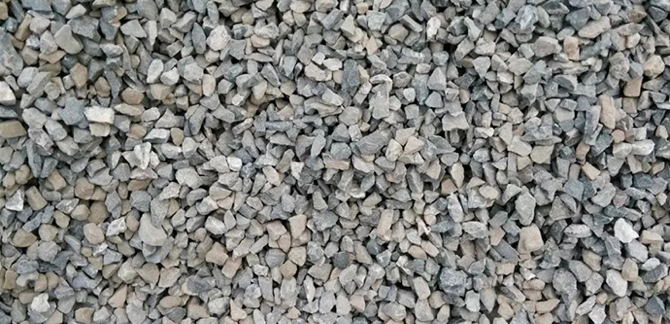

Dolomite is a carbonate mineral with a hardness of 3.5-4 and a specific gravity of 2.85-2.9. It is commonly found in gray-white color and has a similar appearance to limestone. Dolomite can be classified into iron dolomite and manganese dolomite. Due to its versatile properties, dolomite is widely used in building materials, ceramics, glass and refractories, chemical industries, agriculture, environmental protection, and energy-saving applications.

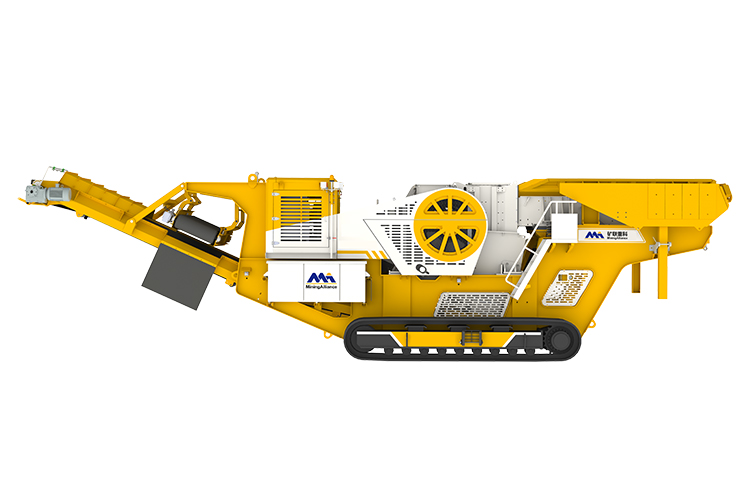

Advantages of Mobile Crushing Equipment for Dolomite

Mobile crushing equipment is highly suitable for dolomite processing due to its flexibility, efficiency, and adaptability to different working conditions. Unlike stationary crushing plants, mobile units can be deployed directly at quarries or near construction sites, minimizing transportation costs and enhancing productivity.

Key Advantages:

- High Mobility: Entire mobile units can move via tracks or wheels to different quarry sites.

- Flexible Crushing Configurations: Can be equipped with jaw crushers, cone crushers, impact crushers, and vibrating screens to suit dolomite hardness and particle size requirements.

- Quick Installation: Modular design enables rapid setup and relocation.

- Reduced Operational Costs: On-site crushing reduces the need for material transport, lowering expenses and saving time.

Typical Mobile Dolomite Crushing Process

A standard mobile dolomite crushing plant includes the following stages:

- Primary Crushing (Mobile Jaw Crusher): Large dolomite blocks are reduced to smaller sizes.

- Secondary/Tertiary Crushing (Mobile Cone/Impact Crusher): The material is further crushed to meet specific size requirements and to achieve good aggregate shape.

- Screening and Conveying: Vibrating screens separate the crushed dolomite into multiple size fractions. Conveyors transfer finished products to storage areas or directly to construction sites.

Features of Modern Mobile Crushing Equipment

Modern mobile crushing units are designed to maximize efficiency, durability, and product quality:

- Stable Performance: Heavy-duty frame and wear-resistant components ensure reliable operation in quarry environments.

- Energy Efficient: Optimized hydraulic and drive systems reduce energy consumption while maintaining high throughput.

- Environmental Friendly: Dust suppression and noise control systems minimize environmental impact.

- Ease of Maintenance: Modular structure, intelligent control, and automatic lubrication simplify maintenance and reduce downtime.

Applications and Case Studies

Mobile crushing equipment has been widely applied in dolomite quarries, construction sites, and industrial mineral processing facilities. For example, in Southeast Asia and Europe, mobile dolomite crushing plants are used to produce aggregates for road construction, cement manufacturing, ceramic fillers, and chemical raw materials. The flexibility and mobility of the equipment allow operators to optimize production across multiple sites efficiently.