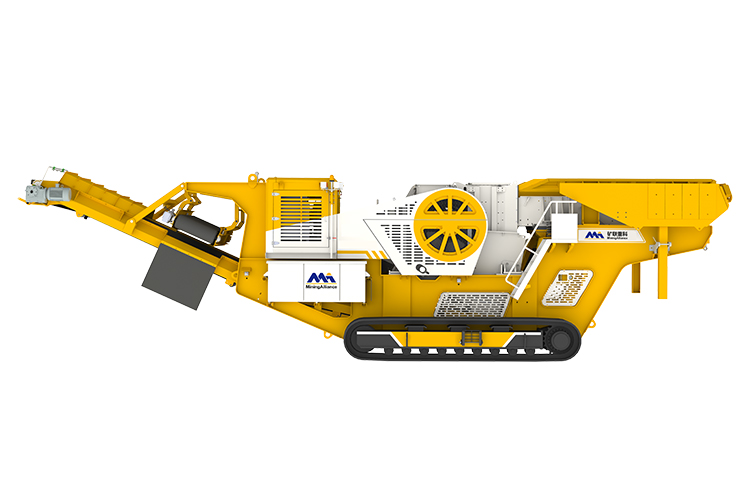

Gold ore is one of the most valuable mineral resources in the world. It contains gold elements or gold compounds that, after beneficiation and smelting, can be turned into high-purity gold products used in finance, jewelry, electronics, and aerospace industries. The process of gold ore beneficiation usually involves multiple stages, including crushing, grinding, classification, and separation. In this process, the mobile crushing station plays a crucial role as the first step in transforming raw ore into valuable concentrates.

Efficient Crushing for Higher Productivity

In gold ore processing, crushing efficiency directly affects the recovery rate and production cost. The mobile crushing station integrates feeding, crushing, screening, and conveying into one compact unit. It can easily move between mining sites, quickly start operations, and flexibly adjust configurations according to different gold ore characteristics. Whether processing hard primary ores or softer oxidized ores, it ensures high-capacity, energy-efficient crushing with minimal manual intervention.

Flexible Mobility and On-site Operation

Traditional fixed crushing plants require complex civil foundations and installation, which are time-consuming and costly. In contrast, mobile crushing stations can be deployed rapidly on-site without foundation work. This makes them ideal for remote gold mines, mountainous areas, or temporary mining operations. The ability to relocate between pits or to follow the mining progress ensures continuous production and reduces material transportation costs.

Stable Performance and Easy Maintenance

The mobile crushing station adopts advanced hydraulic systems and intelligent control technologies, providing stable and reliable performance even under harsh mining conditions. Key components such as vibrating feeders, jaw crushers, and cone crushers are designed for long service life and easy maintenance. Operators can perform routine inspections and part replacements directly on-site, minimizing downtime and improving productivity.

Environmental Protection and Energy Efficiency

Gold mining often takes place in ecologically sensitive areas. The mobile crushing station is designed with energy-saving engines, dust suppression systems, and noise reduction technologies, minimizing its environmental impact. It consumes less fuel compared to traditional stationary setups and reduces dust emissions through closed-loop conveying and spraying systems, fully aligning with modern green mining standards.

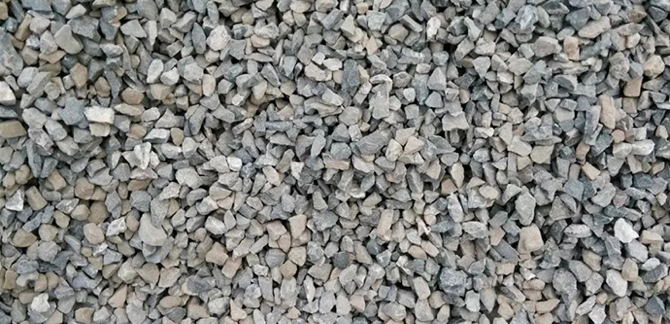

Beneficial for Later Processing

The quality of crushed material is critical for subsequent grinding and separation processes. The mobile crushing station produces uniform and well-shaped particles, creating favorable conditions for downstream equipment. Stable feed size distribution improves grinding efficiency and increases the gold recovery rate during gravity separation or flotation. In addition, consistent crushing performance ensures predictable process control and overall cost reduction.