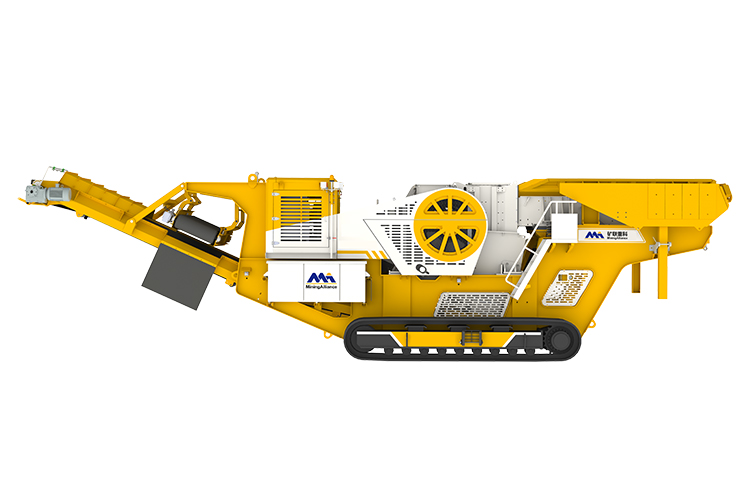

Gabbro is a coarse-grained, dark-colored intrusive igneous rock mainly composed of plagioclase and augite. Known for its hardness, density, and durability, gabbro is widely distributed in the deep oceanic crust and is a common raw material in large-scale construction projects. It is extensively used in producing crushed stone, aggregate bases, high-grade concrete, decorative stone, and road foundation materials. As demand for construction aggregates continues to rise, the mobile crushing station has become an essential piece of equipment for efficient gabbro crushing and processing.

High Efficiency and Strong Adaptability

Gabbro is known for its high hardness and compressive strength, making it difficult to crush using traditional equipment. The mobile crushing station integrates advanced jaw crushers, cone crushers, and impact crushers that are specifically designed for hard rock materials. Its powerful crushing force and optimized chamber design ensure efficient processing and high output while maintaining a consistent particle size. Whether deployed at quarries, mountain mines, or infrastructure sites, it provides stable and reliable performance.

Mobility for On-site Operation

Unlike traditional stationary crushing systems that require foundation work and fixed installation, the mobile crushing station can move directly to the mining or construction site. This greatly reduces material transportation costs and shortens production cycles. For gabbro quarries located in rugged terrain or remote areas, the mobility of the equipment allows quick relocation between working faces, achieving truly flexible and continuous production.

Stable Performance and Easy Maintenance

The structure of a mobile crushing station is compact yet robust. It is equipped with intelligent control systems, automatic lubrication, and overload protection, ensuring safe and stable operation even under high-load conditions. Its modular design also simplifies maintenance — key components such as liners, hammers, and screens can be replaced quickly, minimizing downtime and maximizing productivity.

Environmentally Friendly and Energy Efficient

Modern construction industries are increasingly focused on sustainable development. The mobile crushing station is equipped with dust suppression systems, noise reduction technologies, and energy-saving engines. During gabbro crushing, these systems help reduce dust emissions and fuel consumption, making the equipment compliant with international environmental standards and suitable for green mining projects.

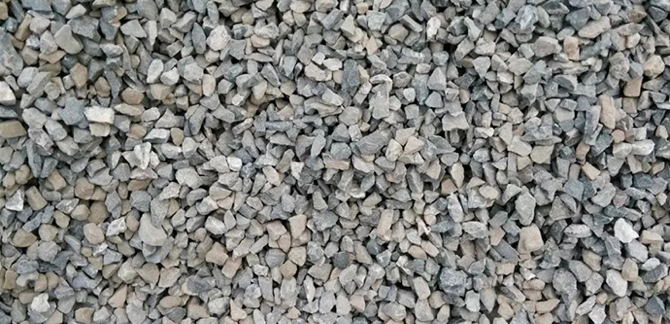

Excellent Aggregate Quality for Later Processing

The crushed gabbro produced by mobile crushing stations features uniform particle size, good cubic shape, and strong adhesion characteristics. These aggregates are ideal for producing high-strength concrete, asphalt mixtures, and road base materials. The stable particle gradation improves the quality of downstream products and enhances overall project durability.