As the demand for sustainable and high-performance construction materials rises, river pebbles—composed primarily of silicon dioxide—have become increasingly valuable due to their hardness, durability, and environmental friendliness. Traditionally used in landscaping and high-grade concrete applications, pebbles now play a key role in eco-friendly construction, and modern processing methods are evolving to match that need.

Challenges in Processing Pebbles

Pebbles are naturally smooth, extremely hard, and resistant to abrasion. These physical characteristics, while advantageous in the final product, pose challenges during processing. Crushing these stones into usable aggregate requires machinery that can withstand high compressive forces and deliver uniform output without excessive wear.

Traditional Stationary Lines vs. Mobile Solutions

Conventional stationary crushing plants involve fixed installation, complex civil engineering, and time-consuming setup. However, with growing demand for flexibility and on-site processing—especially in riverbed or remote mountainous regions—mobile crushing and screening plants have emerged as a game-changer.

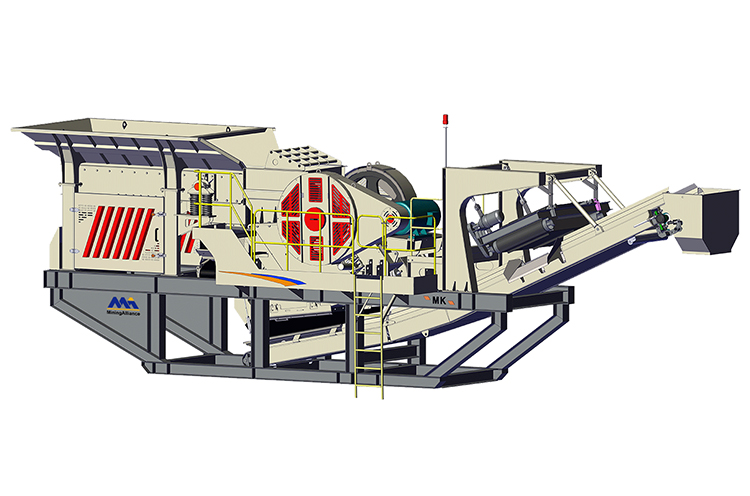

Mobile Crushing Stations in Pebble Applications

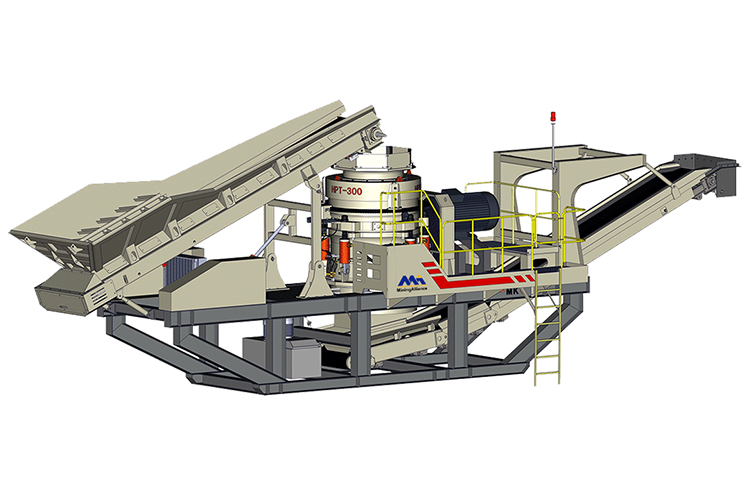

A typical mobile pebble processing line begins with a tracked jaw crusher, which handles primary crushing. Its robust structure is ideal for breaking down large, hard pebbles into manageable sizes. Following this, the material is transferred to a mobile cone crusher, which performs secondary or tertiary crushing to produce uniform, high-quality aggregates.

In many setups, a mobile screening station is integrated to separate fine materials, classify different sizes, and ensure product consistency. This combination of equipment creates a fully mobile production line capable of delivering consistent, high-grade crushed pebble aggregates.

Advantages of Using Mobile Crushing and Screening Plants for Pebbles

- On-site Production: Ideal for pebble sources near rivers or quarries, reducing transportation costs and logistics complexity.

- Flexibility: Easily relocatable, making it perfect for short-term or project-based applications.

- Eco-Friendly: Eliminates the need for hauling raw materials off-site, reducing carbon footprint.

- Energy-Efficient: Advanced mobile systems are equipped with intelligent control, energy-saving engines, and modular design for maximum efficiency.

- Low Operational Cost: With integrated systems, there's less need for auxiliary equipment and labor.

Real-World Application Scenario

In Southeast Asia, a construction firm deployed a full mobile crushing and screening line for a riverside pebble project. The mobility allowed them to move along the riverbed as material was excavated, crushing and screening pebbles directly on-site. Within months, they had produced over 200,000 tons of high-quality aggregates used in local highway subgrades and concrete plants.

Pebbles are a valuable resource for modern construction, and with the adoption of mobile crushing and screening technology, their processing becomes more efficient, sustainable, and cost-effective. Whether it's for large infrastructure projects or smaller-scale commercial developments, mobile plants provide a smart, future-proof solution for pebble crushing.