Feldspar is one of the most abundant minerals in the Earth's crust, widely used in ceramics, glassmaking, and even as a filler in paints, plastics, and rubber. Generally, feldspar appears milk white, but due to the presence of different impurities, it may also take on hues of yellow, brown, light red, or dark gray, and in some rare cases, even exhibit a beautiful iridescence that enhances its decorative value.

The physical properties of feldspar determine the suitable crushing equipment. With a specific gravity between 2.56 and 2.76 and a Mohs hardness ranging from 6 to 6.5, feldspar is considered moderately hard and relatively dense. These characteristics make it necessary to use robust and wear-resistant crushing machinery.

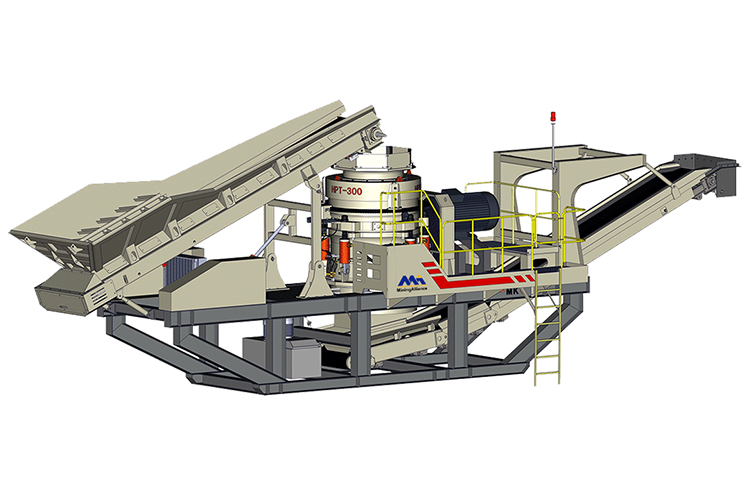

In the crushing process, cone crushers are widely adopted for the middle and fine crushing of feldspar. Thanks to their high crushing ratio, excellent final product shape, and stable performance, cone crushers ensure that the crushed feldspar particles meet the required specifications for downstream applications, such as ceramic body materials and industrial fillers.

For projects with higher demands on particle shape, especially in decorative materials or engineered ceramics, the use of a sand-making machine (impact crusher) may follow the cone crusher to optimize the grain shape and improve the value of the final product.

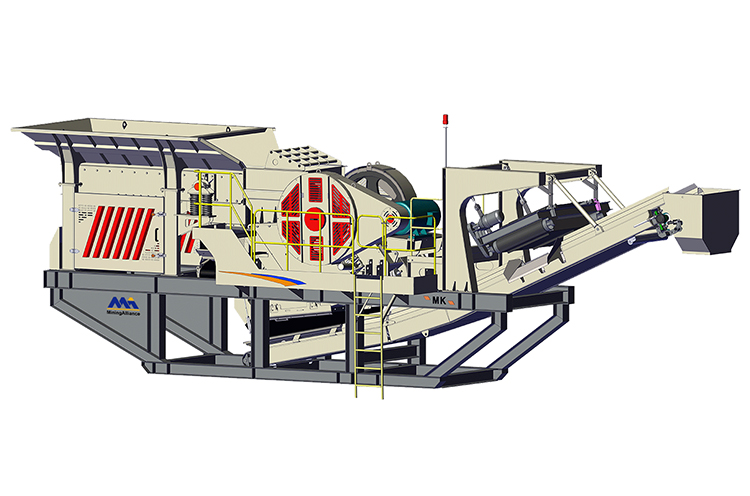

Our mobile crushing and screening stations can be flexibly configured with jaw crushers for coarse crushing, cone crushers for fine crushing, and vertical shaft impact crushers for shaping. This provides a complete and efficient feldspar crushing solution for mines, mineral processing plants, and ceramic material suppliers.