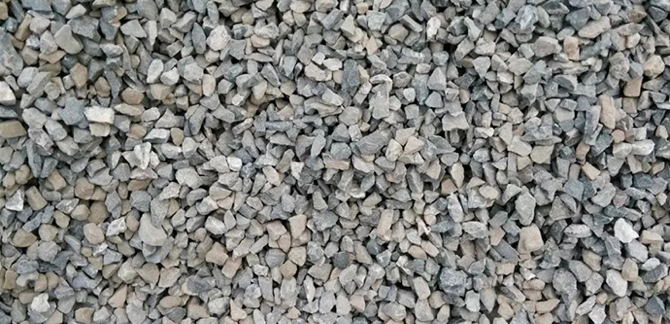

Granite is known for its uniform grain structure, strong hardness, and high resistance to wear, making it an ideal material for producing high-quality, long-lasting aggregates. It is widely used in road construction, railway ballast, building foundations, concrete production, and other infrastructure projects.

The crushing of granite typically involves a multi-stage process. Jaw crushers are commonly used in the primary crushing stage to break down large granite blocks into manageable sizes. After that, cone crushers are employed for secondary and fine crushing, thanks to their ability to handle hard and abrasive stones with high efficiency.

To further enhance the shape and quality of the final product, especially when used for high-grade concrete or road base materials, an impact crusher or sand-making machine can be added to optimize particle shape and grain distribution.

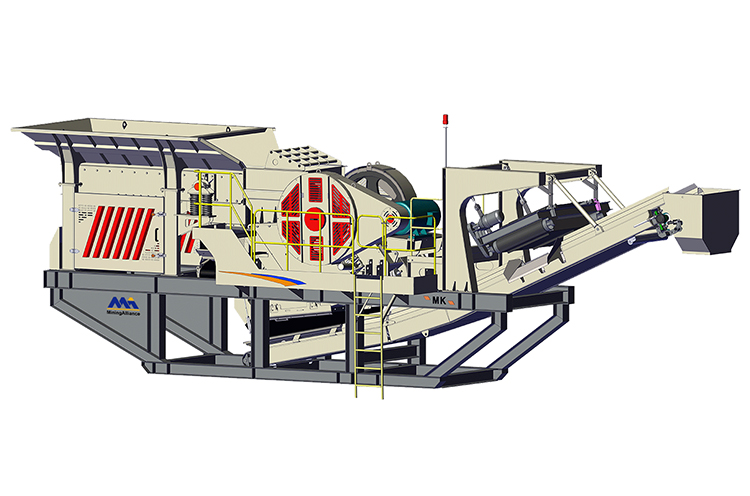

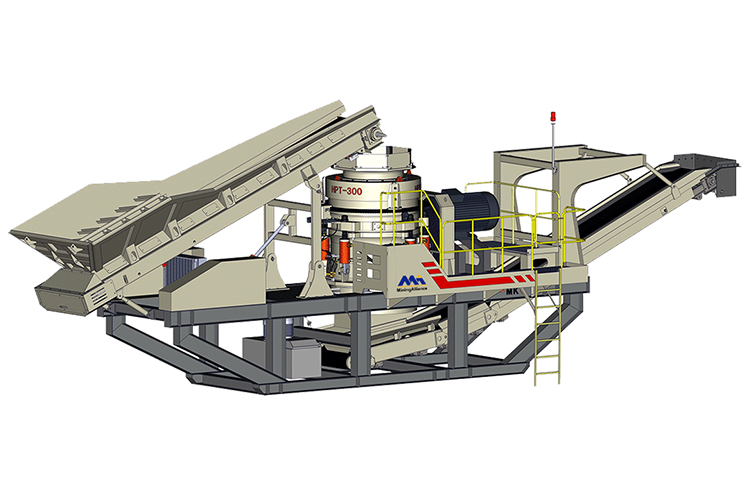

Today, mobile crushing stations have become the preferred solution for granite crushing projects. By integrating the entire crushing process into a mobile platform, they eliminate the need for fixed infrastructure, reduce material transportation costs, and enable on-site processing.

A typical granite crushing setup with mobile equipment includes:

- Mobile Jaw Crushing Station (Primary Crushing)

- Mobile Cone Crushing Station (Secondary/Fine Crushing)

- Optional Mobile VSI Impact Crusher (for shaping and sand production)

Advantages of Mobile Crushing for Granite:

- Flexibility: Quickly deployed at quarries, construction sites, or remote areas

- Efficiency: On-site crushing minimizes logistics and accelerates production

- Durability: Especially designed to handle hard stones like granite

- Product Quality: Achieves excellent grain shape and gradation

Mobile crushing plants for granite are widely used in countries with complex terrain or strict construction schedules. Whether in mountain areas or urban demolition zones, these machines ensure that high-quality granite aggregates are produced efficiently and cost-effectively.