Gypsum is one of the most widely used minerals in construction and industrial applications. Its chemical composition, softness, and binding capabilities make it ideal for manufacturing plaster, wallboards, cement additives, and soil conditioners. However, before it can be used in any of these applications, natural gypsum must undergo a thorough crushing and processing cycle to transform it from raw mineral to usable product.

This article outlines the full process of gypsum crushing and processing, the types of equipment involved, the importance of choosing the right machinery, and the final applications of processed gypsum in various industries.

1. Properties of Gypsum

Gypsum is a naturally occurring mineral composed of calcium sulfate dihydrate (CaSO₄·2H₂O). It typically appears as white or grayish crystals or powder and has a Mohs hardness of about 1.5 to 2. It is very soft and can be easily scratched with a fingernail.

Key characteristics:

- Soft and friable: Makes it easy to crush and grind.

- Soluble in water: Requires moisture control during processing.

- Thermal reactivity: When heated, it loses water and converts to hemihydrate (commonly known as plaster of Paris).

- Non-toxic and abundant: Making it an environmentally friendly material.

2. Gypsum Processing Overview

The gypsum crushing and processing system transforms raw gypsum ore into finished powder or granules for use in industrial and construction products. The process typically involves:

- Primary crushing

- Secondary crushing

- Screening

- Grinding (optional)

- Calcination (for specific applications)

3. Crushing Process

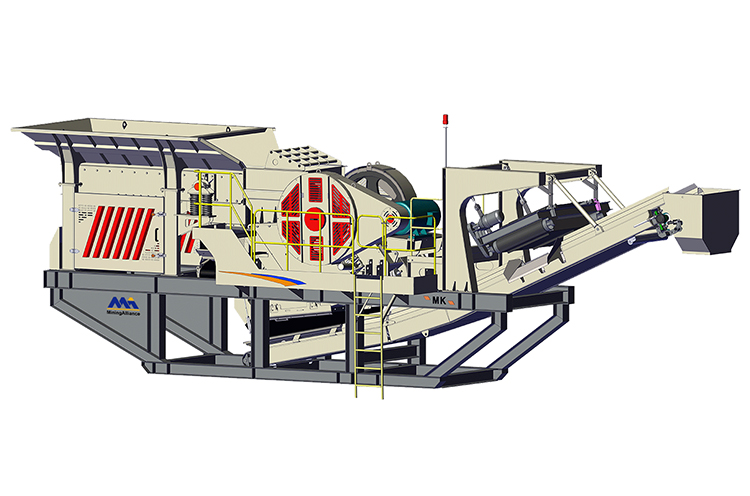

a. Primary Crushing

The first stage is primary crushing, where large gypsum rocks extracted from mines or quarries are fed into a jaw crusher or heavy-duty hammer crusher. These machines are capable of reducing the size of raw gypsum ore from 300–500 mm down to 50–100 mm.

- Recommended Equipment: Jaw Crusher, Hammer Crusher

- Purpose: Break down large chunks of gypsum to manageable sizes for secondary processing.

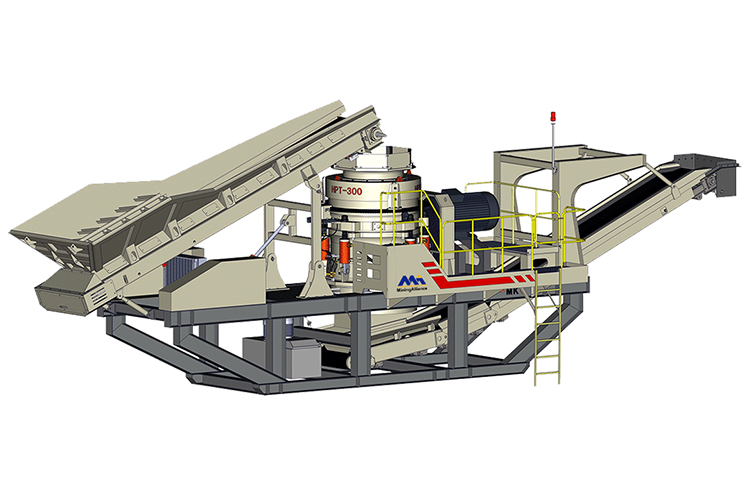

b. Secondary Crushing

After primary crushing, the material is further processed through secondary crushing equipment like impact crushers or fine jaw crushers. This step reduces the material to below 20 mm, suitable for grinding or calcination.

- Recommended Equipment: Impact Crusher, Cone Crusher

- Purpose: Achieve finer particle sizes for higher-quality gypsum products.

4. Screening and Separation

Once the material is crushed to the desired size, it is passed through vibrating screens to separate materials based on size. Oversized particles are returned to the crusher, while appropriately sized material is sent to storage or further processing.

- Equipment Used: Vibrating Screens, Belt Conveyors

- Purpose: Ensure uniform size distribution, remove impurities or oversized rocks.

5. Optional: Grinding and Pulverizing

In applications where fine gypsum powder is required—such as for plaster, gypsum board, or chemical use—additional grinding is necessary. The material is fed into a gypsum grinding mill (Raymond mill, vertical mill, or ball mill) to achieve a powder size of 100–300 mesh.

- Recommended Equipment: Raymond Mill, Vertical Mill, Ball Mill

- Purpose: Achieve precise particle size for industrial use and reactivity control.

6. Calcination (for Finished Products)

For applications like plaster or gypsum board production, calcination is essential. This process involves heating the gypsum to around 150–170°C to remove the water of crystallization, converting gypsum to calcium sulfate hemihydrate (CaSO₄·½H₂O).

- Equipment: Rotary Kilns, Fluidized Bed Furnaces

- Output: Plaster of Paris or stucco used in wall coatings and drywall.

7. Equipment Selection Considerations

Choosing the right gypsum crushing and processing equipment is critical for efficiency, durability, and end-product quality. Factors to consider include:

- Moisture content of raw gypsum

- Capacity requirements

- Final product size

- Energy consumption

- Ease of maintenance

High-quality crushing systems are equipped with dust suppression systems and wear-resistant liners to ensure long service life and environmental compliance.

8. Applications of Processed Gypsum

Once processed, gypsum is used across multiple industries:

Construction:

- Drywall boards

- Plaster and wall coatings

- Cement additive (retarder)

- Floor screeds

Agriculture:

- Soil conditioner

- pH adjustment in acidic soils

- Improving water infiltration and structure

Industrial Use:

- Molds for ceramics and dental use

- Filler in paints and plastics

- Desulfurization in flue gas treatment (FGD gypsum)

Energy & Environment:

- Synthetic gypsum from power plants used similarly to natural gypsum

- Helps in land reclamation and waste treatment

9. Benefits of Modern Gypsum Crushing Systems

Modern crushing and processing systems offer many benefits:

- Energy efficiency: Advanced motors and intelligent controls reduce power consumption.

- Automation: Touch-screen PLC systems for real-time monitoring and adjustments.

- Modularity: Equipment can be tailored to different production scales.

- Environmental compliance: Integrated dust collectors, noise control, and moisture handling.

10. Conclusion

Gypsum is a versatile and essential material across industries, and efficient crushing and processing is the first step in unlocking its full potential. With the right combination of crushing, screening, grinding, and calcination, high-quality gypsum products can be produced for everything from construction to agriculture and industrial applications.

Whether you are building a new gypsum production line or upgrading an existing one, selecting high-performance equipment tailored to your capacity and product goals is key to long-term profitability and product quality.