Introduction of Lead-Zinc Ore Processing

Lead-zinc ore is a key non-ferrous metal resource, widely used in industries such as metallurgy, machinery, electricity, and chemicals. In the beneficiation process, crushing is the first and most crucial step. With the development of modern mining, mobile crushing stations have gradually replaced traditional fixed crushing plants, offering higher flexibility, efficiency, and environmental adaptability.

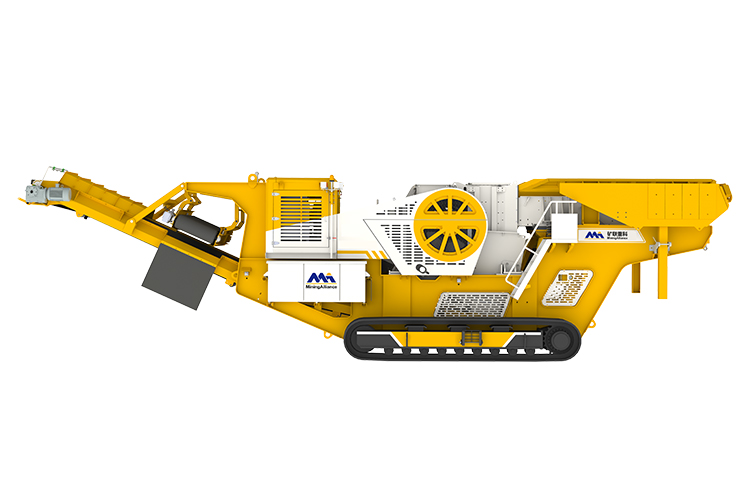

Advantages of the Mobile Crushing Station in Lead-Zinc Ore Processing

Compared with fixed crushing lines, the mobile crushing station has multiple advantages:

- Flexible Mobility – It can be quickly transferred between different mining sites, reducing infrastructure investment and relocation time.

- Integrated Design – The station integrates feeding, crushing, screening, and conveying systems, forming a complete processing line.

- High Efficiency and Energy Saving – The intelligent control system optimizes power distribution, improving crushing efficiency and reducing energy loss.

- Easy Maintenance – Hydraulic control and modular components make maintenance more convenient and reduce downtime.

- Environmental Adaptability – Equipped with dust suppression and noise reduction systems to ensure compliance with green mining standards.

Lead-Zinc Ore Crushing Process Using Mobile Station

The typical process for lead-zinc ore with a mobile crushing station is as follows:

- Feeding: Raw ore is loaded by an excavator or loader into the mobile feeder.

- Primary Crushing: The material enters the mobile jaw crusher for coarse crushing.

- Secondary Crushing: The crushed ore is conveyed to a mobile cone crusher or impact crusher for further size reduction.

- Screening and Classification: The onboard vibrating screen separates materials according to particle size.

- Transportation: Qualified materials are directly transported to the next stage, while oversized materials are returned for re-crushing.

This integrated process not only simplifies plant layout but also improves production efficiency and ensures uniform particle size.

Project Performance and Customer Feedback

Mining Alliance’s mobile crushing stations have been widely used in lead-zinc ore projects in Southeast Asia, Africa, and the Middle East. Customers report that the equipment performs stably even under high-load conditions, and its mobility greatly reduces on-site construction time and cost.

In a Malaysian lead-zinc mine, for instance, a 200TPH mobile crushing line designed by Mining Alliance achieved over 98% equipment availability rate, significantly improving ore processing capacity and concentrate recovery rate.