Limestone is one of the most abundant mineral resources on Earth, and it plays a critical role in a wide range of industries such as construction materials, cement manufacturing, metallurgy, chemical engineering, and environmental treatment. Due to its widespread availability, limestone can easily meet the material demands of various projects.

After simple beneficiation—such as washing, screening, or removing surface impurities—limestone can be used as a high-quality industrial material. To transform it into the proper size and shape for specific uses, crushing becomes a necessary step.

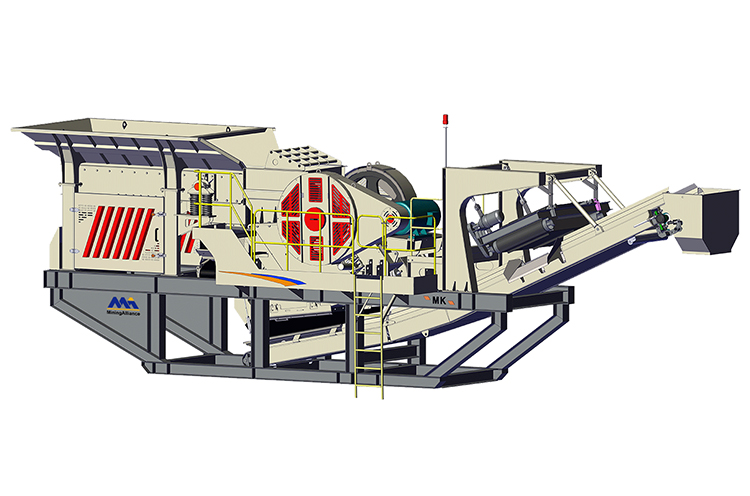

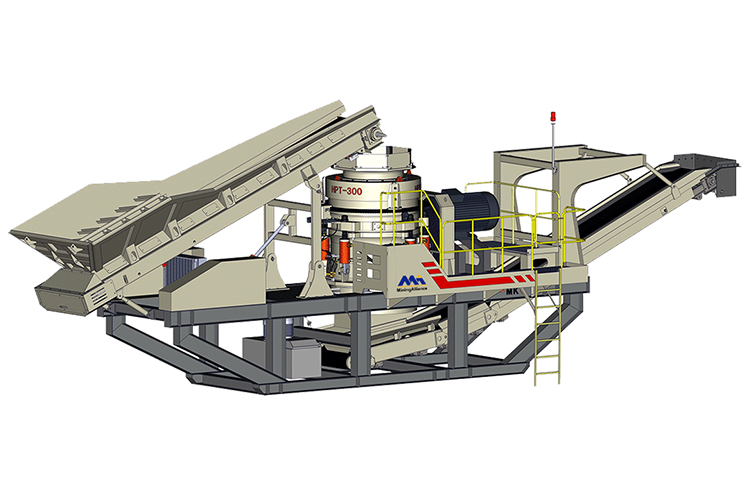

In the traditional fixed crushing process, jaw crushers are typically used for primary crushing, breaking large limestone rocks into smaller sizes. For secondary or tertiary crushing, cone crushers or impact crushers are commonly used depending on the final product requirements. However, in modern production, mobile crushing stations offer a more efficient and flexible solution.

Mobile crushing plants integrate feeding, crushing, screening, and conveying systems into a compact unit. They can be equipped with jaw crushers, impact crushers, or cone crushers depending on the application. For limestone processing, a common setup is:

Mobile Jaw Crusher (for coarse crushing) + Mobile Cone or Impact Crusher (for fine crushing).

This mobile configuration offers several key advantages:

- Flexibility: Easily moved between different job sites or limestone quarries.

- Efficiency: On-site processing reduces transportation costs and speeds up construction timelines.

- Adaptability: Can handle different grades and moisture levels of limestone with minimal adjustment.

- Environmental Protection: Reduced dust generation and noise compared with traditional fixed plants.

Today, mobile crushing stations are widely used in limestone mining, infrastructure construction, cement raw material preparation, and even in environmental projects like desulfurization and waste recycling.