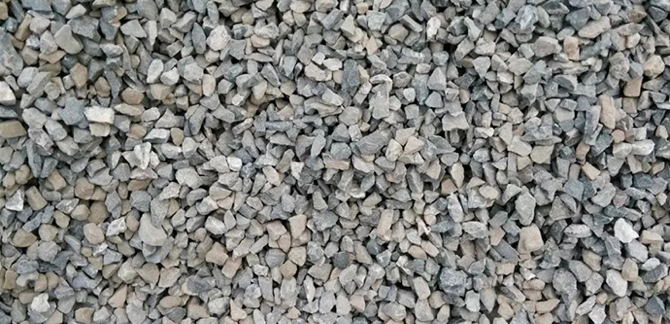

Basalt, known for its exceptional hardness and wear resistance, is increasingly utilized in infrastructure projects that require materials capable of withstanding high stress and erosion. With a Moh’s hardness between 5 and 7, and a silica (SiO₂) content of up to 52%, basalt is an ideal raw material for cast stone manufacturing and high-performance aggregates. However, processing basalt on traditional fixed crushing lines presents significant challenges—especially in remote or mountainous regions where equipment transportation and site development are limited.

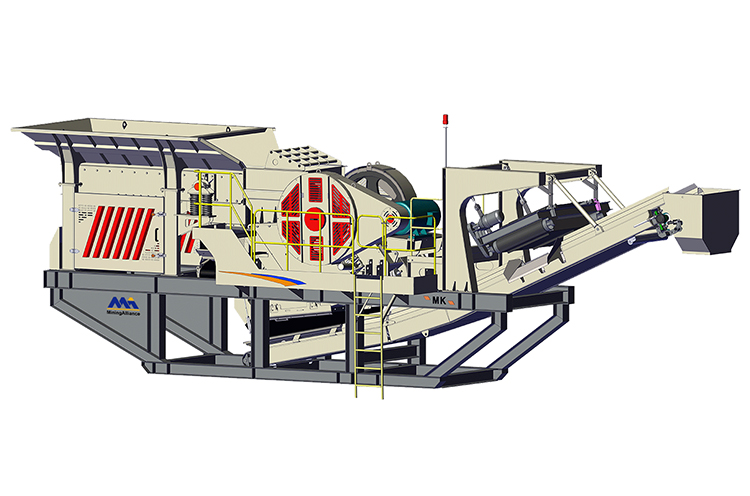

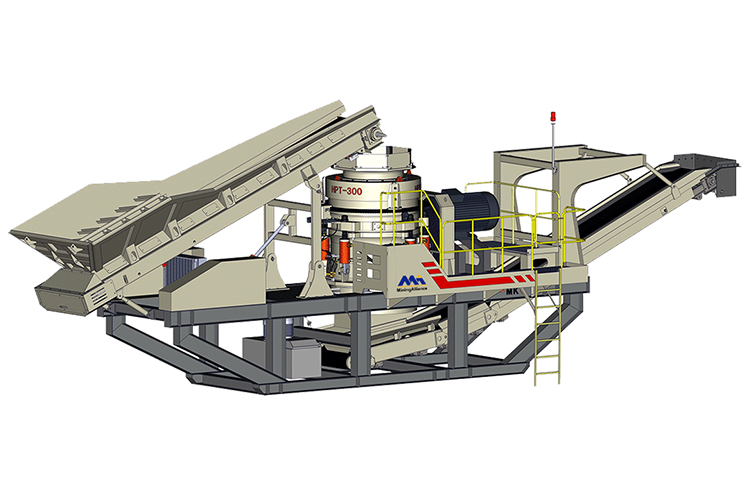

Mobile crushing and screening stations offer a practical solution by eliminating the need for a permanent foundation and enabling on-site processing. These stations are equipped with powerful jaw crushers to perform primary crushing, breaking the basalt into manageable chunks. Cone crushers are then utilized for secondary and tertiary crushing stages, delivering finely graded aggregates with minimal flakiness and optimal shape. The flexibility of mobile platforms allows deployment in rugged terrain and rapid repositioning from one project site to another, making them an excellent choice for road building, railway construction, and hydropower station development.

Additionally, mobile systems help reduce transportation costs and carbon emissions by processing the basalt close to the extraction point. This not only improves project efficiency but also aligns with global sustainability goals. The integration of vibrating screens and intelligent dust suppression systems further enhances operational performance, ensuring compliance with environmental regulations.

Moreover, many mobile crushing stations now incorporate advanced control systems featuring real-time monitoring of crusher load, feed rate, and wear conditions, enabling predictive maintenance and minimizing downtime. Such automation improves safety and allows operators to adjust crushing parameters remotely for different basalt grades, ensuring consistent product quality.

Furthermore, mobile plants can be customized with modular components such as magnetic separators to remove ferrous contaminants and water spray systems to suppress dust, which is critical when working near environmentally sensitive areas or urban settings. The compact footprint and ease of transport also reduce site disruption and setup time.