As urban development accelerates, the volume of construction waste is increasing rapidly. Traditional methods such as landfilling and open dumping consume valuable land resources and cause severe environmental pollution. To promote the reduction, recycling, and harmless treatment of construction waste, mobile crushing stations—particularly tracked models—are playing a critical role.

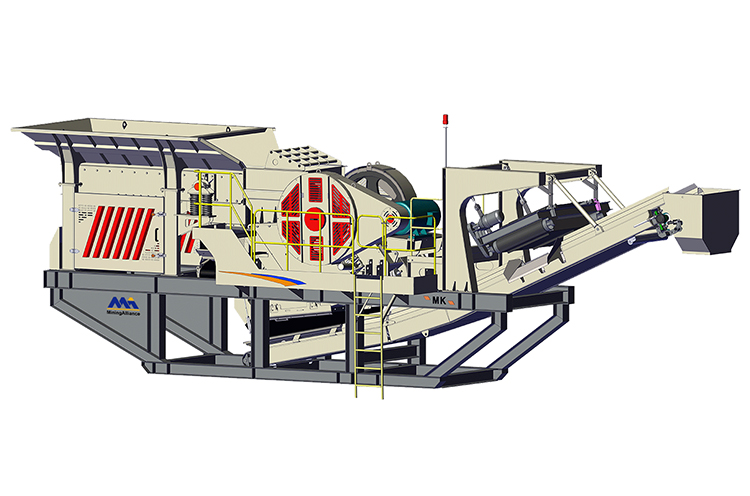

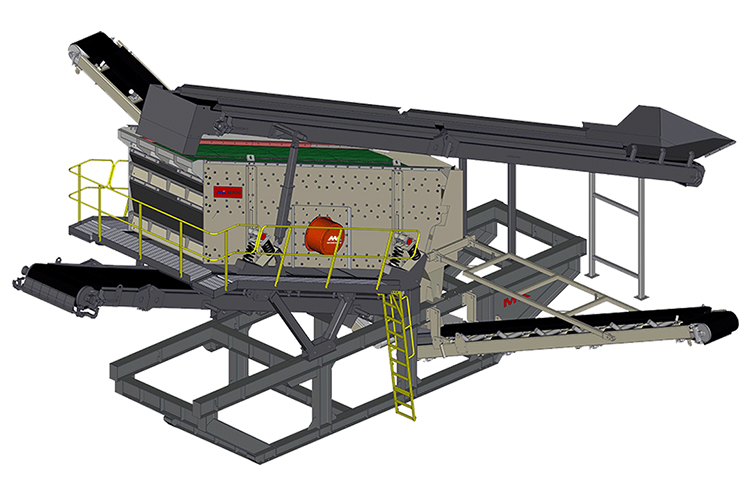

Tracked mobile crushing stations feature a compact structure and strong mobility, enabling them to drive directly into demolition sites. Integrating feeding, crushing, screening, and conveying into one unit, these machines require no complex infrastructure and can be rapidly deployed, significantly improving processing efficiency. Depending on the type of material, users can equip jaw, impact, or cone crushers to handle concrete debris, bricks, and rebar-laden waste with high efficiency, covering all stages from primary to fine crushing.

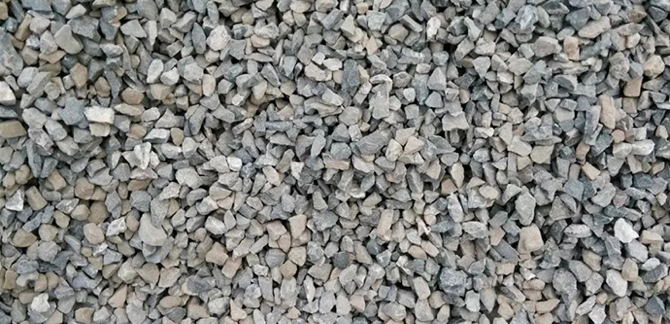

More importantly, the processed aggregates can be reused on-site or in the production of recycled bricks, concrete mixes, or road base materials—turning waste into valuable resources and reducing construction costs and raw material consumption.

The stations are equipped with advanced dust suppression systems and noise-reduction features, making them ideal for operations in urban environments with strict environmental regulations. Intelligent systems allow for remote control and real-time data monitoring, ensuring safer and more efficient operations. The hybrid diesel-electric powertrain enables flexible adaptation to site conditions while reducing fuel consumption and carbon emissions.

With many municipalities now incorporating construction waste recycling into their urban policies, mobile crushing stations are becoming indispensable tools. They not only address the problem of ever-growing construction waste piles but also support the development of a circular economy and promote the practice of green building strategies.